Application scenario: Applied to visual inspection of process. The product have been applied in 10+ projects in display panel industry

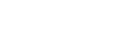

Product function

– Object detection、Image classification、Image segmentation

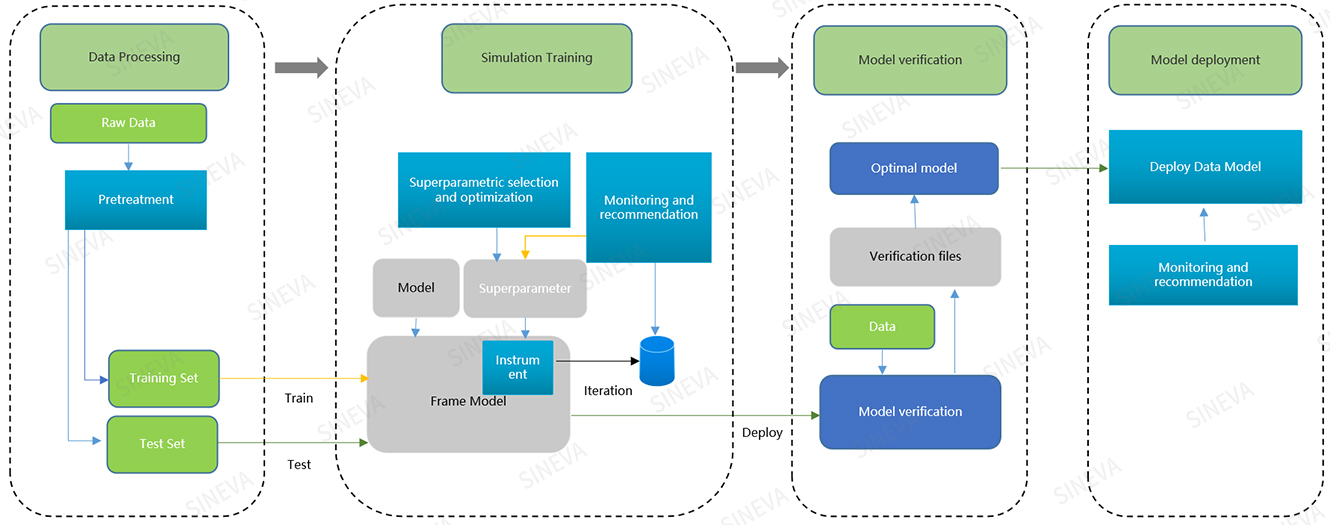

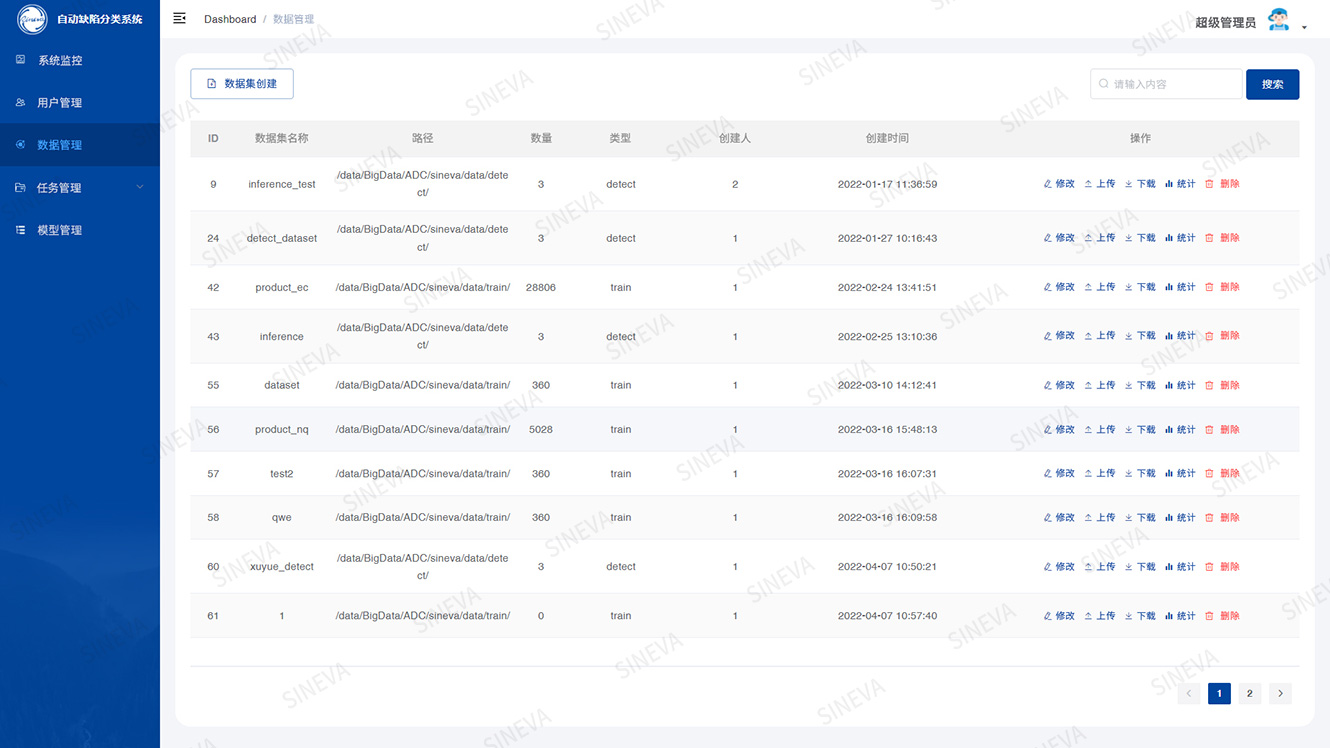

– Model management: train、inference

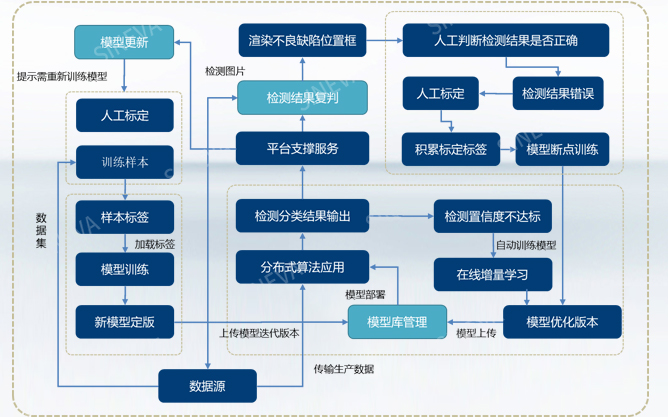

– Data management

– Senior judgement

– Monitoring and early warning

– High availability

Product features

– Reduce quality inspection cost

– Precipitate knowledge and skills

– Improve detection capability dynamically

– Promote comprehensive process improvement

Advantage effect

|

|

Customer oriented product design, which can reduce the quality inspection cost by 85% and promote the comprehensive improvement of process |

|

|

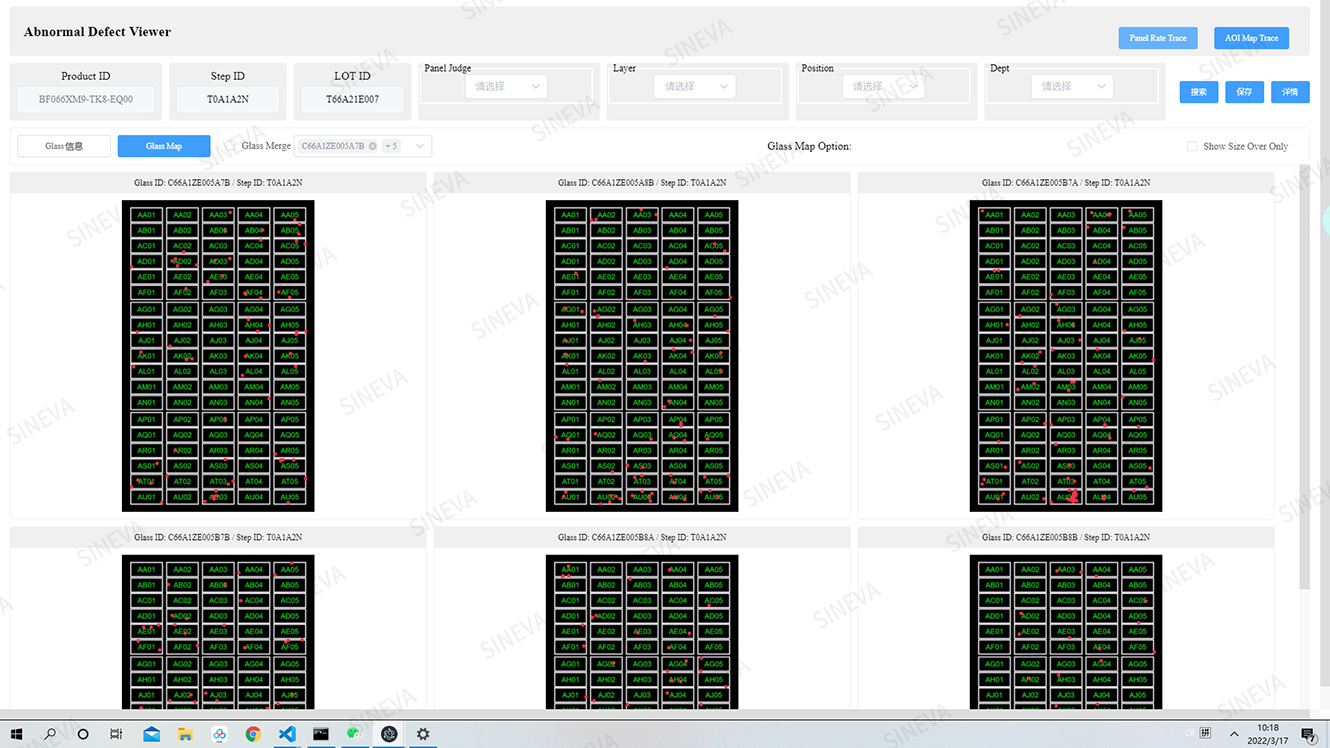

The training process is visualized, the model results are clearly visible, and the model effect is clear at a glance |

|

|

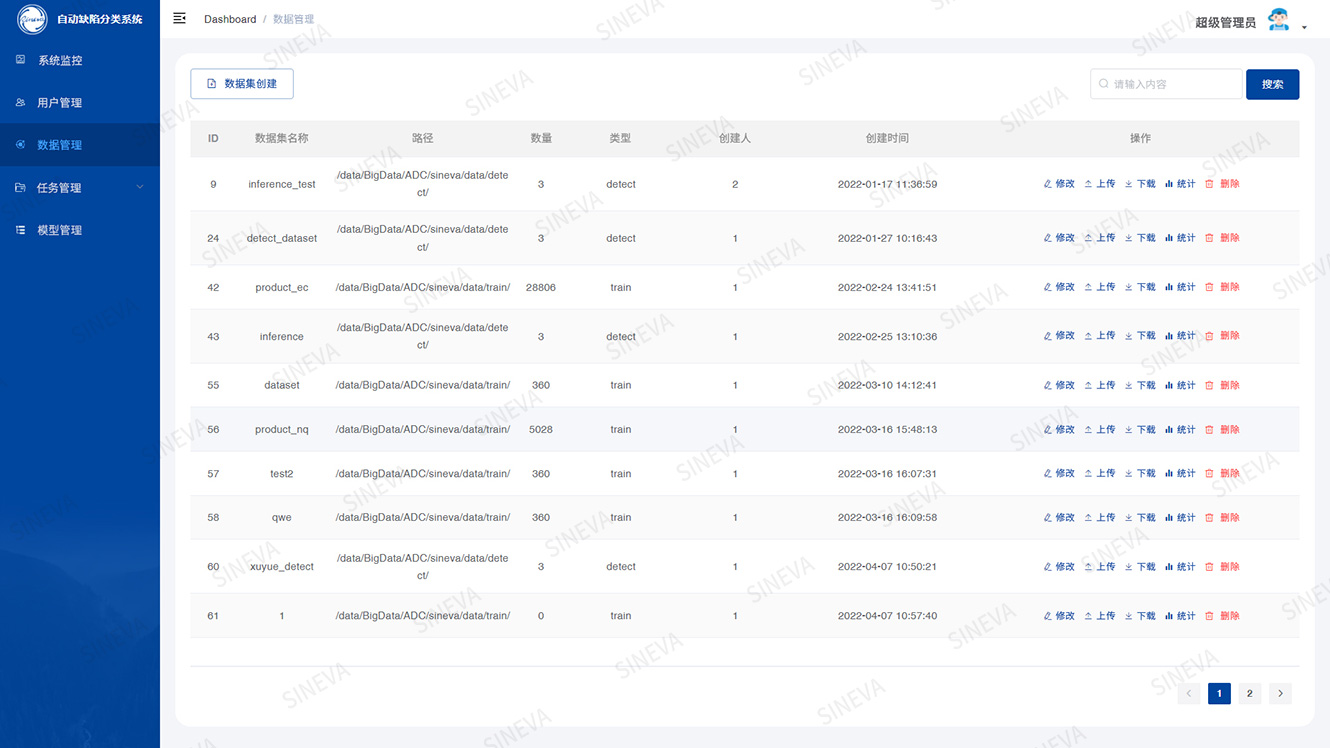

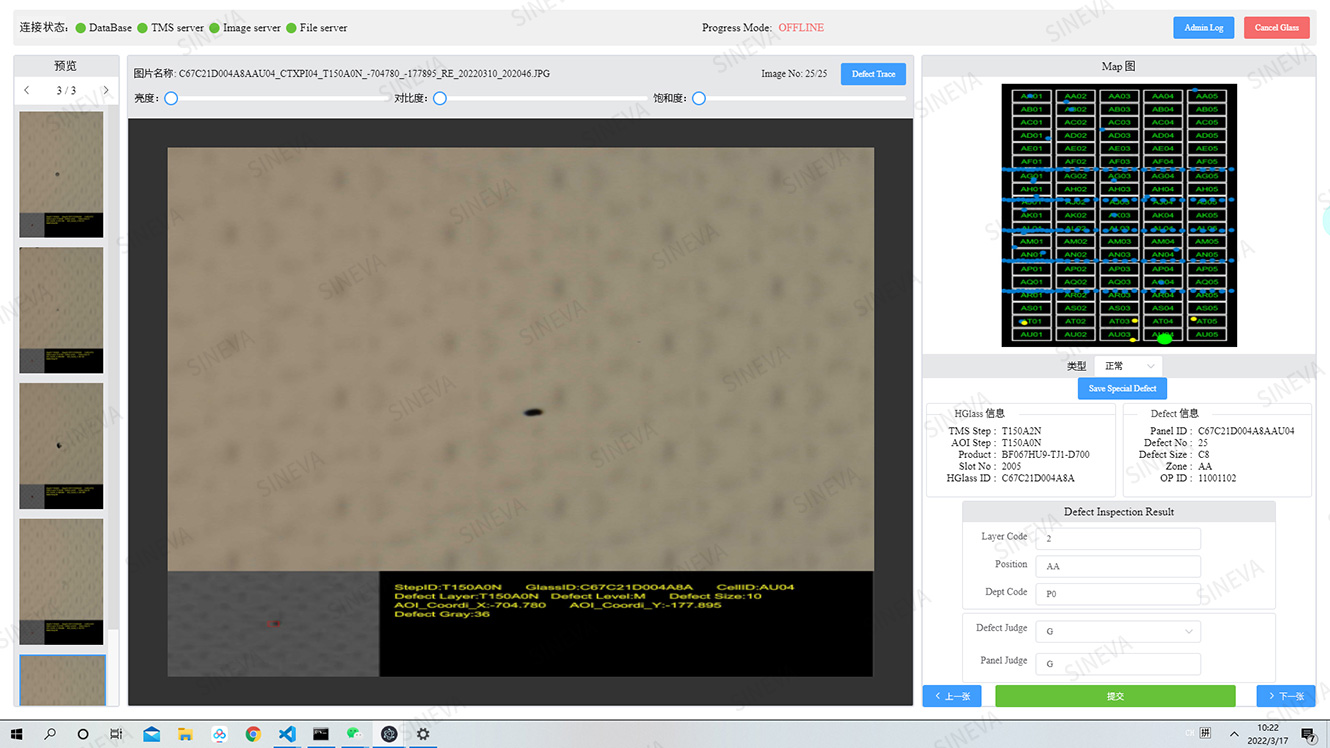

Manual judgment, to complement the automatic judgment |

|

|

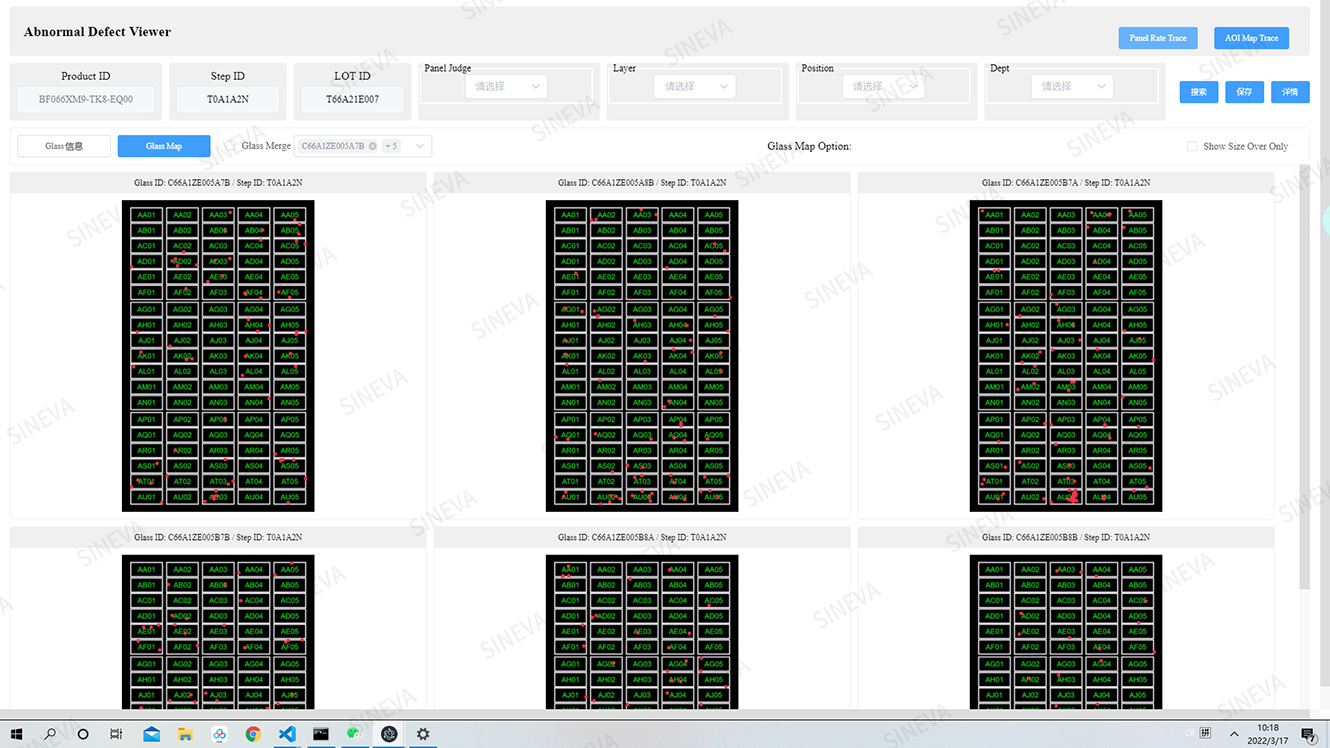

Rich data analysis functions, with front layer traceability, map analysis, similarity analysis, decision analysis and other functions |

Cases

※A international leading pan-semiconductor enterprise case

|

|

• Business challenges

1. Many kinds of defects (100+) and difficult to sort 2. Manual judgment with low accuracy and efficiency 3. Lack of AI talent

4. Traditional thinking 5. Lack of methods to find out high-value and applicable scenarios

|

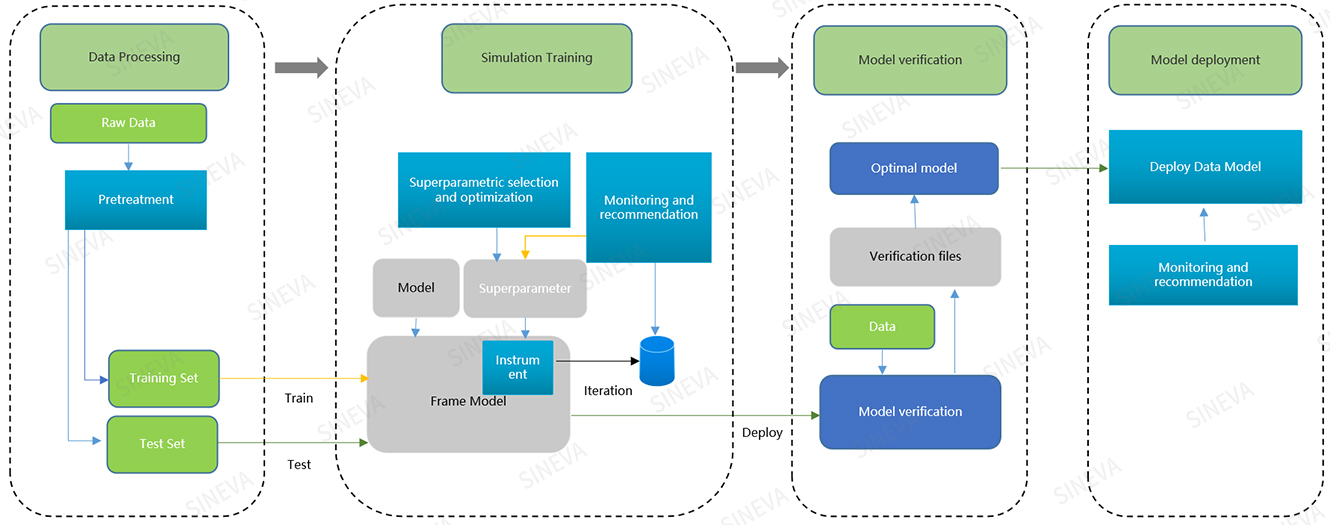

• Solution

|

|

• Effect of solution

1、Automatically judges the map, the personnel replacement rate is 80%, and the accuracy rate is improved by 20% 2、Reduce quality inspection cost by 85% 3、Improve product quality, reduce non-quality cost (scrap, etc.) 4、Provide root cause analysis of product defects 5、5 + people have learned to use and iterate the existing machine learning model 6、Established the flow system of defect detection

|

Advantage effect

|

|

Customer oriented product design, which can reduce the quality inspection cost by 85% and promote the comprehensive improvement of process |

|

|

The training process is visualized, the model results are clearly visible, and the model effect is clear at a glance |

|

|

Manual judgment, to complement the automatic judgment |

|

|

Rich data analysis functions, with front layer traceability, map analysis, similarity analysis, decision analysis and other functions |

Cases

※A international leading pan-semiconductor enterprise case

|

|

• Business challenges

1. Many kinds of defects (100+) and difficult to sort 2. Manual judgment with low accuracy and efficiency 3. Lack of AI talent

4. Traditional thinking 5. Lack of methods to find out high-value and applicable scenarios

|

• Solution

|

|

• Effect of solution

1、Automatically judges the map, the personnel replacement rate is 80%, and the accuracy rate is improved by 20% 2、Reduce quality inspection cost by 85% 3、Improve product quality, reduce non-quality cost (scrap, etc.) 4、Provide root cause analysis of product defects 5、5 + people have learned to use and iterate the existing machine learning model 6、Established the flow system of defect detection

|

Back to list

Back to list