Hefei Sineva Intelligent Machine Co., Ltd. was established in 2013 and is a leading provider of advanced pan-semiconductor high-end equipment in China. The company focuses on the research, development, production, sales, and technical services of pan-semiconductor vacuum coating equipment, clean transfer equipment, and high-speed high-precision equipment. Guided by national strategic needs, Hefei Sineva addresses industry challenges and supports sector development, serving numerous tier 1 clients within the global pan-semiconductor supply chain across displays, integrated circuits, and photovoltaics. With cutting-edge technology and relentless innovation, Hefei Sineva has become a crucial enabler in the pan-semiconductor manufacturing sector.

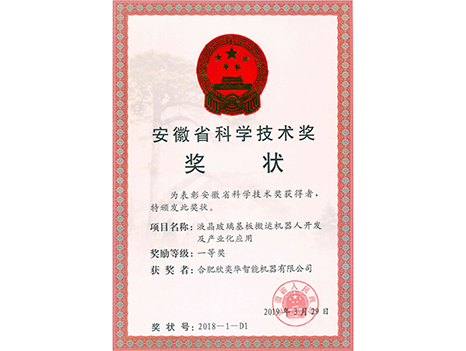

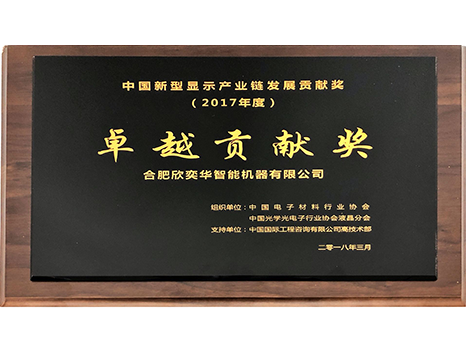

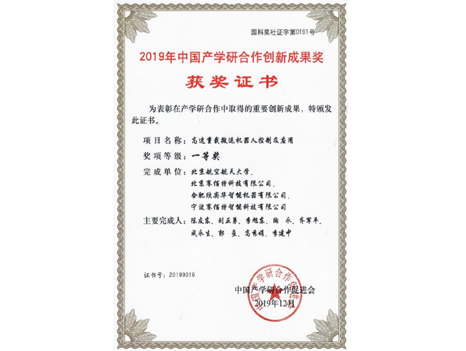

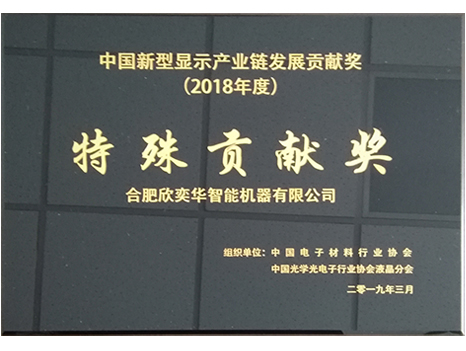

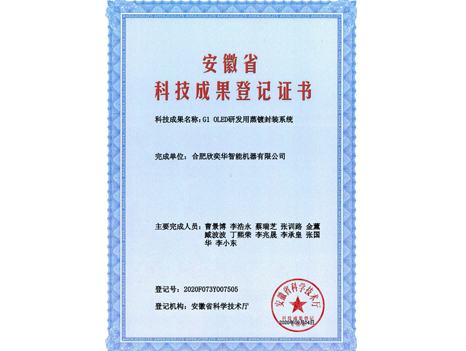

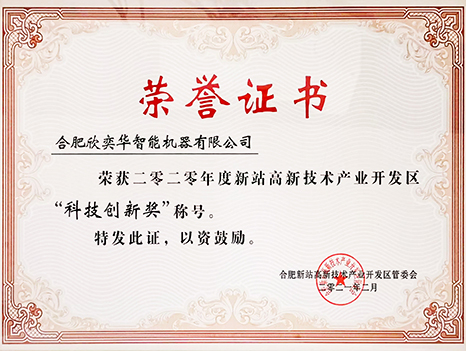

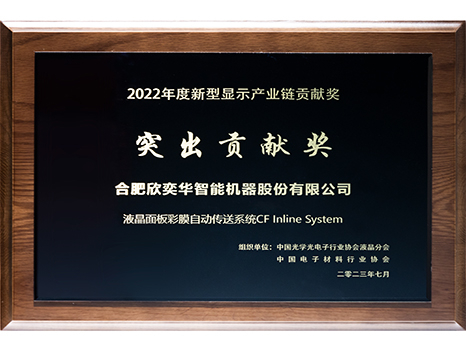

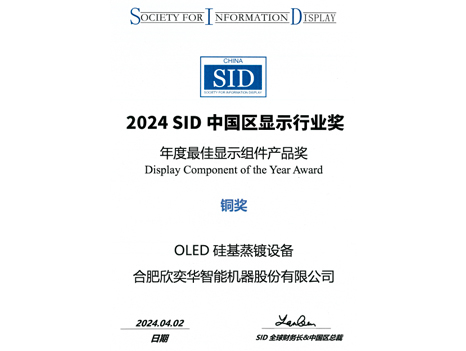

Hefei Sineva's 80,000-square-meter research and manufacturing base is located in Hefei New Station District. As a national high-tech enterprise, the company leads and participates in multiple national key research and development plans, contributes to the development of industry standards, and has been recognized at the 2021 National "13th Five-Year Plan" Science and Technology Innovation Achievement Exhibition. Hefei Sineva has been honored with numerous awards, including the China Industry-University-Research Collaboration Innovation Achievement Award (First Prize), Anhui Science and Technology Award (First Prize), and Anhui Quality Award, among others.

Through continuous research and development, Hefei Sineva has overcome key technical challenges in the industry, establishing three major product and technology platforms: vacuum coating, clean transfer, and high-speed high-precision equipment. These platforms enable Hefei Sineva to focus on displays, integrated circuits, and photovoltaics, developing a range of advanced equipment that maintains a competitive edge in diversified business expansion.

Vacuum Coating Technology:

Since 2015, Hefei Sineva has been dedicated to OLED display panel vacuum coating technology research and development, aiming to solve the industrialization challenges of OLED panel vacuum coating. Display vapor deposition equipment is the core process equipment for OLED display panels, previously dominated by foreign manufacturers. Hefei Sineva has successfully developed a series of domestic G1 to high-generation display vapor deposition equipment, with key core components such as small-generation equipment, evaporation sources, and high-precision alignment systems for high-generation vapor deposition equipment delivered to customers for mass production applications. Through innovative design of heating and cooling units, and the development of relevant control devices and programs, Hefei Sineva ensures precise control of the evaporation temperature field, enabling particle evaporation under the material equilibrium vapor pressure, achieving an internationally advanced level of film thickness uniformity ≤3%.

In 2020, Hefei Sineva applied its OLED vacuum coating technology innovation to the core process of perovskite solar cell manufacturing and quickly completed development and mass production applications with leading customers. This technology transfer reduces research and development costs, accelerates product mass production and iteration. In the perovskite photovoltaic field, Hefei Sineva has developed a series of perovskite vapor deposition equipment products from pilot to GW-level mass production, providing key equipment support for the large-scale production of perovskite batteries. Currently, all four GW-level mass production lines invested in globally use equipment developed by Hefei Sineva.

Clean Transfer Technology:

Hefei Sineva primarily provides high cleanliness and high-precision material handling and transportation technology for core process steps such as etching, coating, and photoresist development in display panels, integrated circuits, and other fields, ensuring efficient and high yield mass production of core process steps. In the integrated circuit field, Hefei Sineva's semiconductor automated material handling system (AMHS) is mainly applied to the wafer handling and storage of core process steps such as lithography, etching, and coating, realizing intelligent and high-speed material handling between core process steps and ensuring stable and efficient production. Hefei Sineva is one of the few domestic enterprises to break foreign monopolies and has achieved stable mass production applications in several domestic 8-inch and 12-inch semiconductor customer wafer fabs. In the semiconductor display field, Hefei Sineva has solved the technical challenges of handling large, thin, and fragile glass substrates for G6-G10.5 product lines and developed clean transfer robots for intelligent substrate handling and transportation in core process steps such as etching, coating, and photoresist development in semiconductor displays, ensuring production efficiency and product yield in high cleanliness environments.

High-Speed High-Precision Technology:

Hefei Sineva primarily focuses on technological breakthroughs and development for advanced packaging in new display and integrated circuits, achieving industrial application of key core equipment in related fields. In advanced packaging for integrated circuits, Hefei Sineva primarily addresses the core process technology of high-speed and high-precision placement for advanced packaging, meeting the strict requirements of placement speed and accuracy in the advanced packaging field. Through innovative technology development, Hefei Sineva has realized direct high-speed flip-chip placement technology, which is more than 5 times faster than the traditional placement technology dominated by foreign companies, significantly improving customer production efficiency and reducing production costs. In new semiconductor displays, Hefei Sineva has developed micron-level LED chip high-speed and high-precision mass transfer technology, developing the world's first large-size Mini LED mass transfer equipment for batch production. Additionally, Hefei Sineva has completed the development of Micro LED laser mass transfer equipment, which has been delivered to customers for mass production applications.

Hefei Sineva, with years of technology and experience accumulation, has formed five major product lines and six technology development and design centers based on vacuum coating, clean transfer, and high-speed high-precision technologies, improving the reusability of common technology development and design, becoming an important force driving the independentization of China's high-end equipment manufacturing process. Hefei Sineva has successfully expanded into multiple industry fields and will continue to focus on high-end manufacturing equipment, improve industrial layout, and promote faster and better industry development, contributing to China's high-level science and technology self-reliance with innovative technical capabilities and deep industry experience.

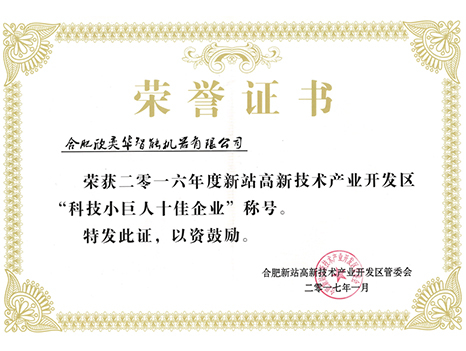

- Honor Certificate

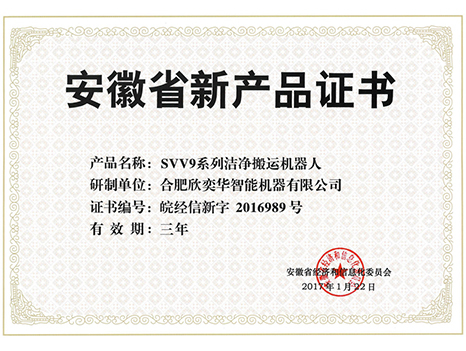

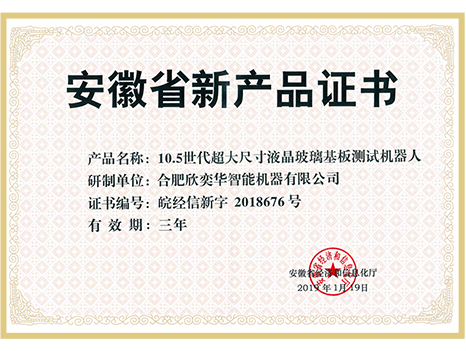

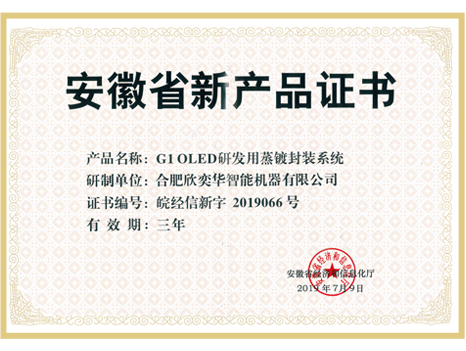

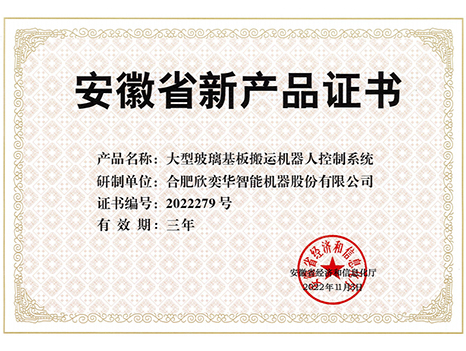

- Certifications

Leveraging its profound foundation in independent research and development, Hefei Sineva Intelligent Machine Co., Ltd. has successfully established a formidable technological moat centered on its proprietary intellectual property. The company is certified under the Ministry of Industry and Information Technology's (MIIT) "Specifications for the Industrial Robot Industry." It has also been recognized with numerous innovation platform designations, including the Anhui Provincial Engineering Research Center for Robotics in New Display Applications, the Anhui Provincial Enterprise Technology Center, the Anhui Provincial Industrial Design Center, and the Anhui Provincial Postdoctoral Research Workstation. Hefei Sineva has assembled an international R&D team composed of highly educated talent and overseas experts, and has built a comprehensive R&D system that underscores its formidable independent innovation capabilities.

Hefei Sineva Intelligent Machine Co., Ltd. has established five major Technology Centers and six major Design Centers. The five Technology Centers—covering Mechanical Power, Mechatronic Systems, Motion Control, Overhead Hoist Transfer (OHT) Algorithms, and Optical Research—provide the underlying technical support for product innovation. The six Design Centers—spanning Mechanical Design, Electrical Design, Software Design, AI Innovation, Vision Positioning, and Robotic Integration & Application—ensure the efficient progression of products from R&D to full-scale production and implementation. The company has led or participated in four National Key R&D Programs, undertaken two projects under the National Electronic Information Industry Revitalization and Technical Transformation Program, led one Anhui Provincial Major Science and Technology Project, and spearheaded the development of one industrial robot industry standard. Furthermore, eight of its products have been certified as "Anhui Provincial First-Set Major Technical Equipment."

-

Our vision

Committed to becoming the world's leading enterprise in the field of intelligent machines

-

Our mission

Provide exciting products and services for all walks of life and all households, make a contribution to China's modernization and human civilization

Provide exciting products and services for all walks of life and all households, make a contribution to China's modernization and human civilization -

Our humanistic environment

Simple and harmonious interpersonal relationship, The principle of loyalty and gratitude, competitive and enterprising life attitude, the team spirit of concerted efforts

-

Our core values

Innovation and enterprising, right way management and pursuit of excellence. We pursue the organic unity of enterprise economic growth and social responsibility actively with unique corporate social responsibility policy

-

Staff Care

Staff CareWe respect employees and protect their legitimate rights and interests in accordance with the law. We do not employ any form of compulsory or involuntary labor, child labor, and do not discriminate against employees for religion, race, gender, political opinion, geography and color. And all jobs are voluntary for employees. In the recruitment and daily management, we follows the principle of equal and voluntary management, there is a reasonable suggestion channel to understand the aspirations of employees. In addition, the company has also set up a labor union to provide complaint and appeal channels for employees. The requirement for company's talent is to be visible during usual time, stand out at the crucial moment , take on task bravely under the critical moment.

We are committed to establishing a perfect salary and welfare system, providing employees with many aspects benefits, such as commercial insurance, children's education, physical examination, shuttle bus, dormitory and other non-cash benefits, so as to help poor employees with serious diseases. At the same time, we organize employee birthday parties regularly, caring lectures and other activities to care for the difficulties in employees' life or work and relieve their pressure.

We pay attention to the training for talents, and provides full and equal learning and training opportunities for employees. Combining employees' own development with enterprise development, providing a multi-channel development platform for employees, supporting employees to choose their development channels according to their own abilities and interests freely, and help employees grow and realize their self-value.

-

Safe and credible

Safe and credibleWe have a thorough and perfect security strategy and measures to ensure the company's network security and privacy protection, and has a perfect information security emergency response system and data security protection system. We keep investing to build an open, transparent security environment and improve the software engineering ability and practice comprehensively, build the network resilience, create credible high-quality products, and ensure the stable operation of the network and business continuity.

In terms of production safety, we have formed a complete set of perfect safety management system, including factory production safety management regulations, enterprise safety culture construction, safety emergency organization system and work flow, safety training content, and held regular staff tests to check if they comprehend safety content for ensuring production safety.

-

Greens Environmental Protection

Greens Environmental ProtectionWe are committed to reducing the environmental impact from production, operation processes, the whole life cycle of products and services, meanwhile promoting energy saving, emission reduction and circular economy development in various industries through innovative products and solutions. Moreover we keep leading all parties in the industrial chain to build a low-carbon society and achieve carbon neutrality.

We adhere to the integrity and compliance management, continuously strengthen risk management of sustainable development, pay attention to employee development and value realization, carry out the responsible management of sustainable development of the global supply chain, make a contribution to the operating community, and work with all parties in the industrial chain to build a harmonious and healthy business ecology.

-

Corporate Social Responsibility

Corporate Social ResponsibilityThe growth and expansion of enterprises are inseparable from the support of society. We never forget to return to society, spread positive energe, focus and devote to charity and other social welfare activities frequently, practice corporate social responsibility by conducting social welfare activities, for example, donating to Henan’s continuous flood, caring fire rescue officers, visiting elderly activities, helping poor students with critical diseases, and poverty alleviation from Hefei poor mountain. In addition, we also support the front line against COVID-19 using our technical force. We encourage and lead employees to undertake social welfare activities with more positive enthusiasm to contribute to the sustainable development of the society.