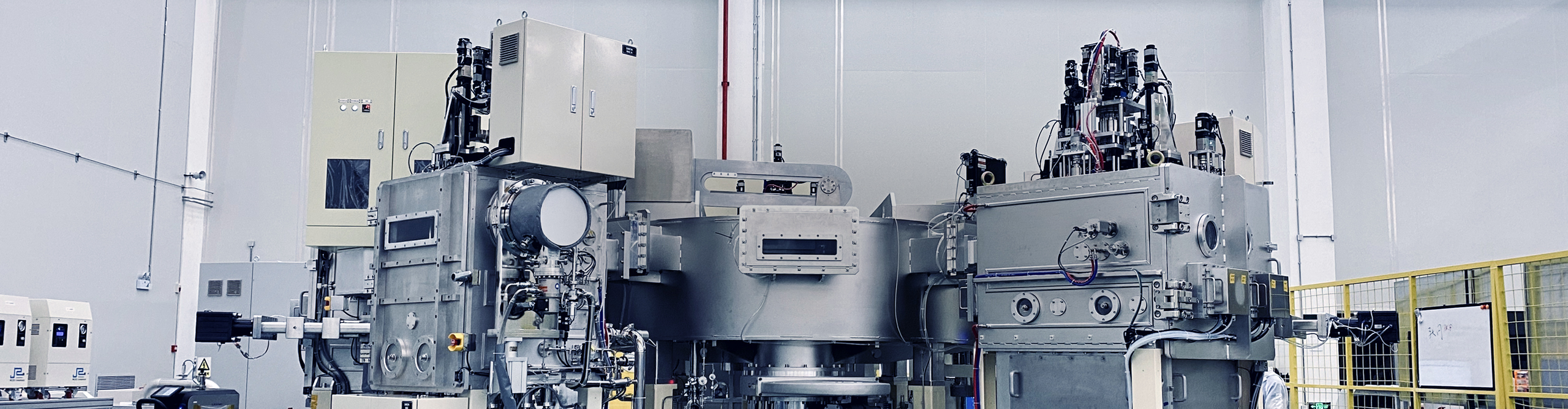

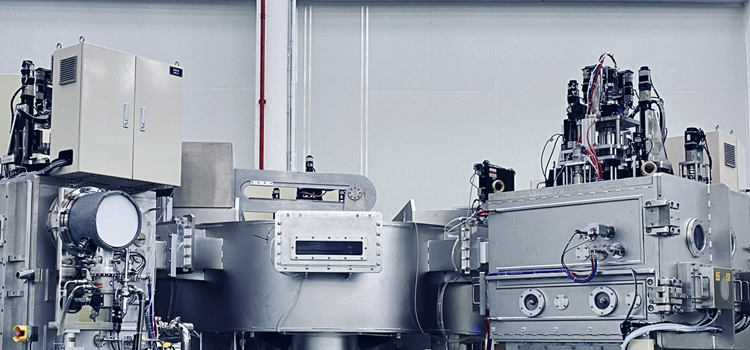

Application scenario: In the manufacturing process of Mini LED display panel and backlight (glass /PCB), inspect the bad appearance of products after die bond and furnace

Product features

– Automatic modeling according to CAD files, automatic optimization of detection path

– The minimum resolution is micron level

– Automatic normalization, accuracy up to millimeter level

– LED offset detection accuracy micron level, Angle detection accuracy <0.1°

– Real-time data interaction with die-bonder, and correct possible Die Bonding defects

– Compatible with LED position white oil and pad detection

Core Technology

– Effectively improve TT and reduce equipment vibration by COF (capture on fly) technology

– Free inspection path planning technology

– High precision inspection and measurement algorithm

Back to list

Back to list