Product features

– WMS/WCS control system

– Low error rate

– Save storage area

– Reduce warehouse workers

– Save sorting time

– Seamless connection with ERP / MES and other systems

– Big data fault diagnosis and prediction

Core Technology

– Warehouse management and control

– Multi-vehicle operation and control

– High-speed sorting

– Fault diagnosis and prediction

– Logistics program animation and simulation technology

Cases

|

|

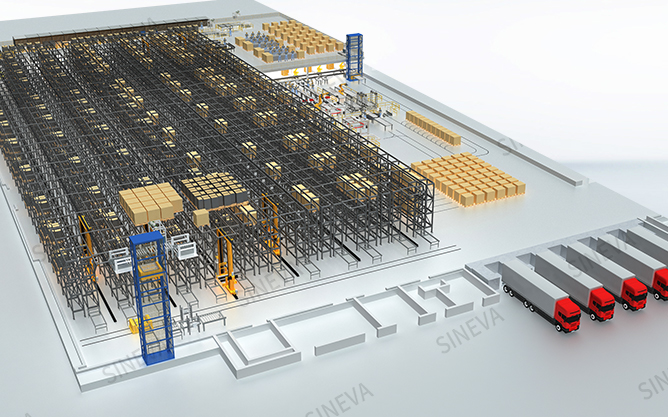

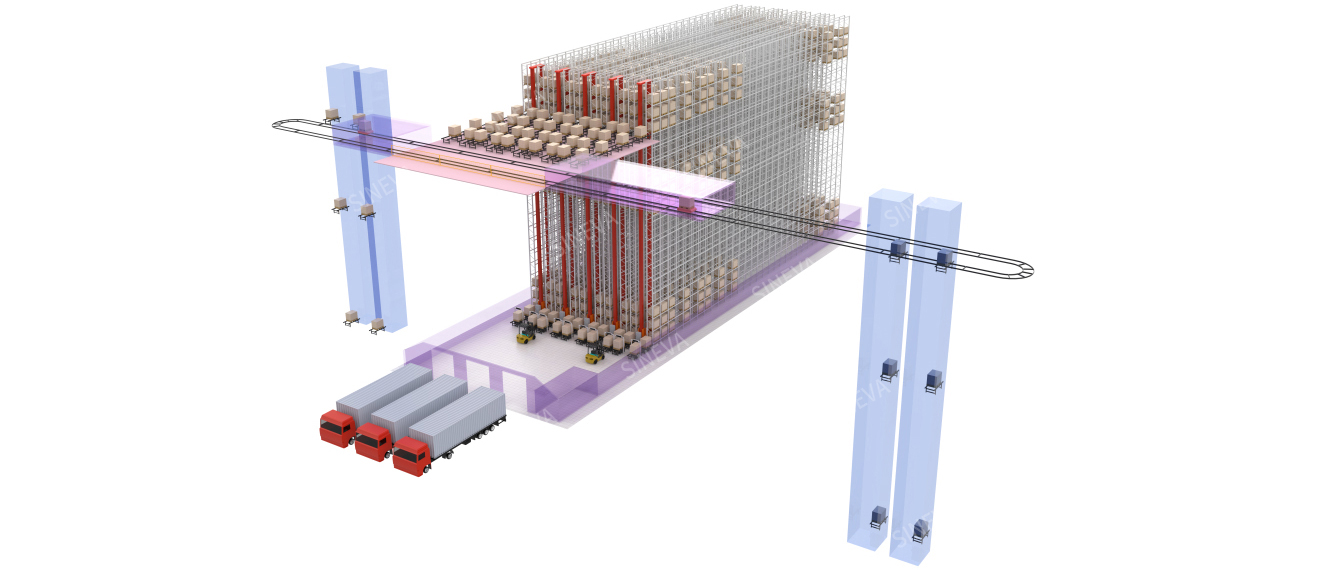

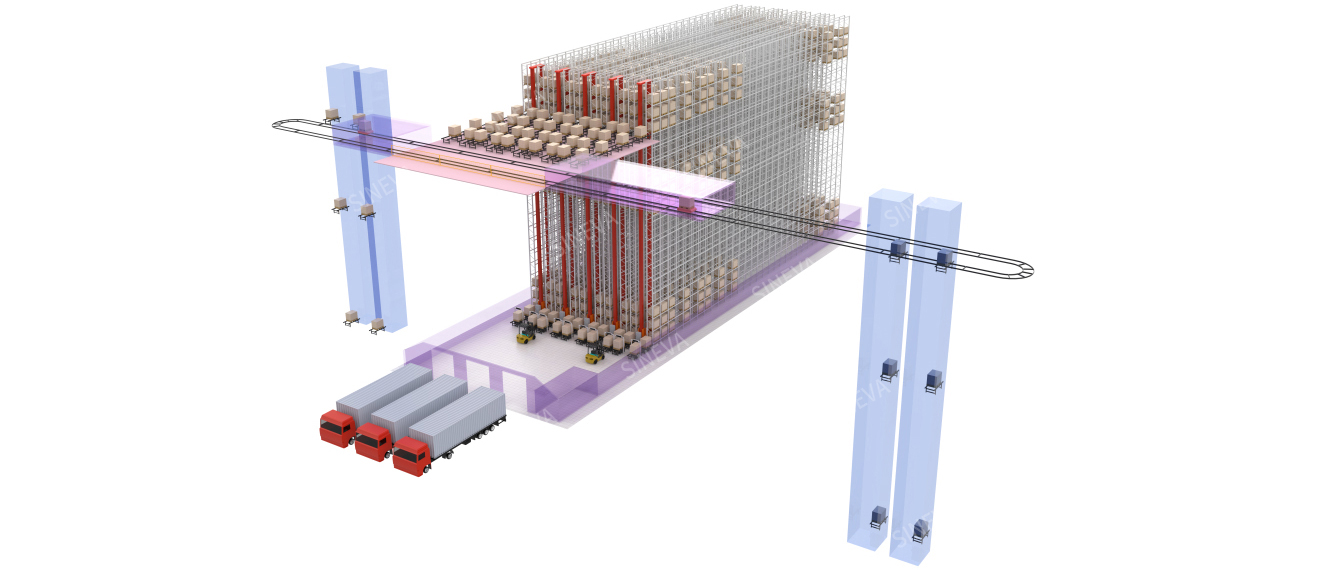

※ The three-dimensional warehouse of a domestic 3C leading enterprise This intelligent warehouse solution has 4236 storage spaces, 5 double stretch stackers, 1 single stretch stacker, 1 double station linear shuttle, 1 WCS( Warehouse Control System) and 1 WMS( Warehouse Management System). The intelligent warehouse system is based on automatic storage equipment, high-rise shelves and advanced information management system, meet material storage needs, and improves the level of warehouse management. It improves warehouse operation efficiency through automated storage system, and the efficiency of storage materials in and out of the warehouse, reduce freight losses and investment in human resources, improve warehouse utilization which can bring economic benefits to enterprises. |

|

|

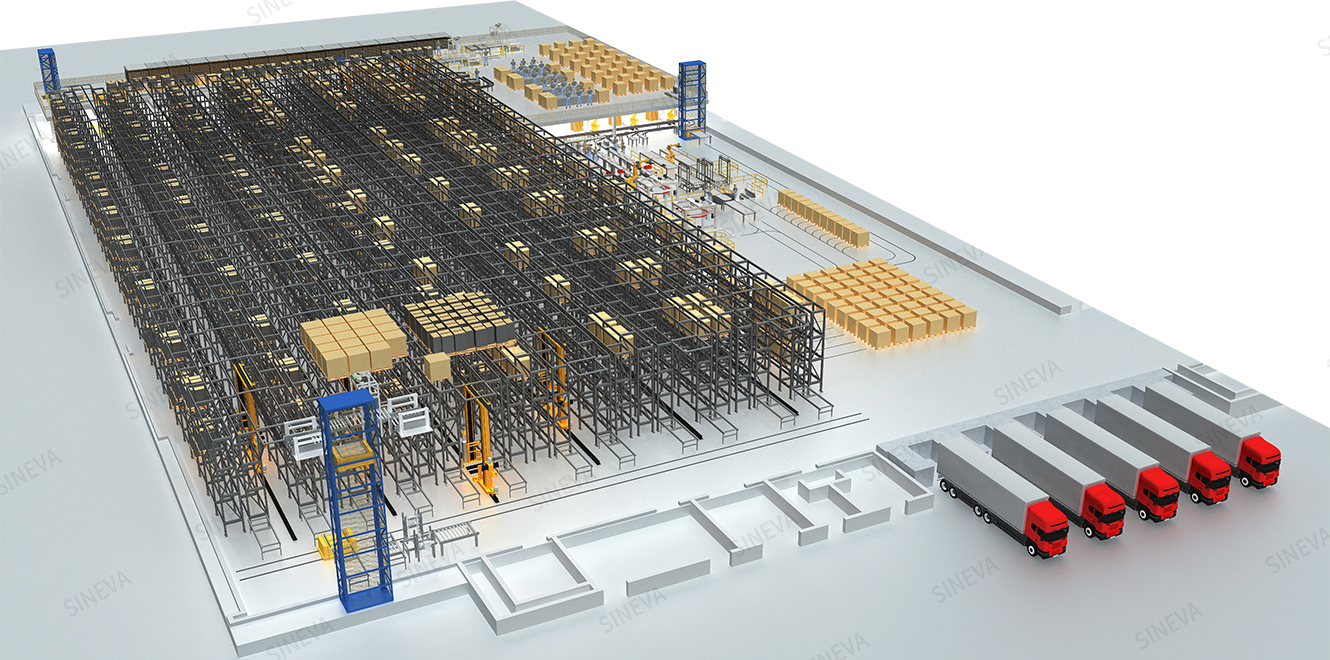

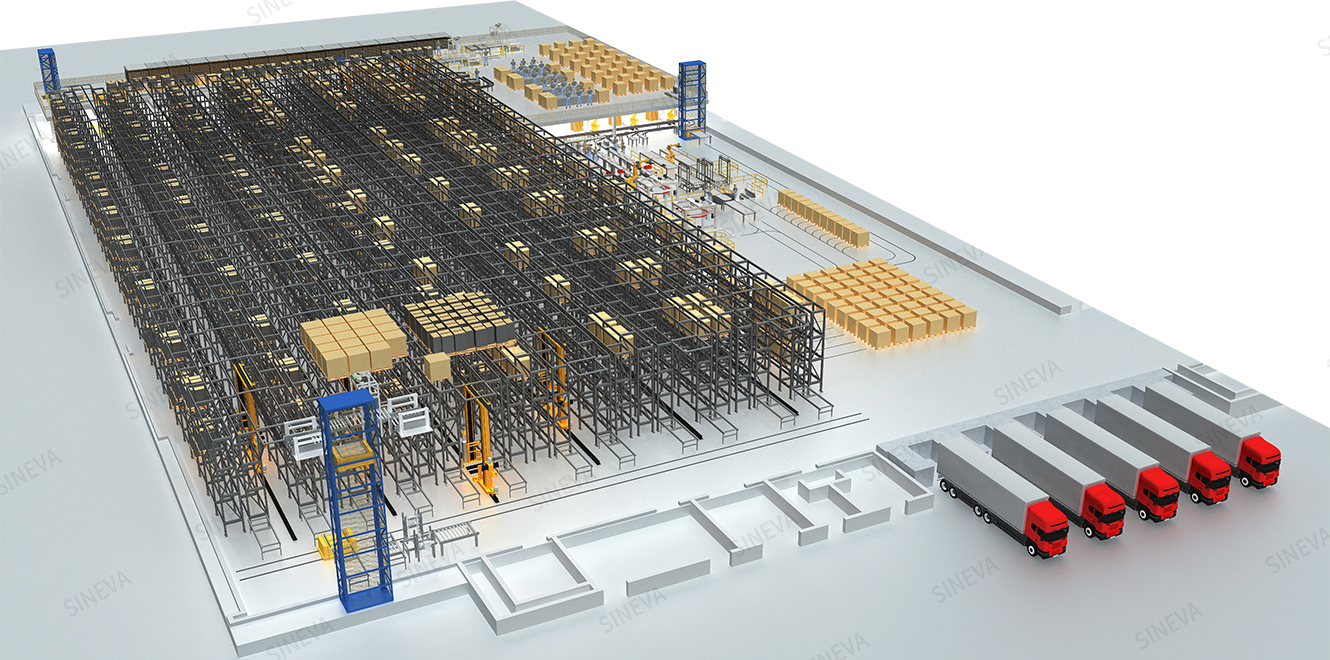

※ Three-dimensional warehouse of a domestic HVAC enterprise The intelligent Warehouse System has 8336 storage spaces, 12 heavy duty 1.5T stacker, double stretch stackers, 1 single stretch stacker, 4 one-track two-car systems, 1 SLV System, 1 WCS( Warehouse Control System) and 1WMS( Warehouse Management System). The automated three-dimensional warehouse realizes warehouse automation and transparent management information, and plans an automatic warehouse out and loading system, the seamless connection of material flow and information flow can be realized through the intelligent transfer line and the upstream production and processing workshop. |

|

|

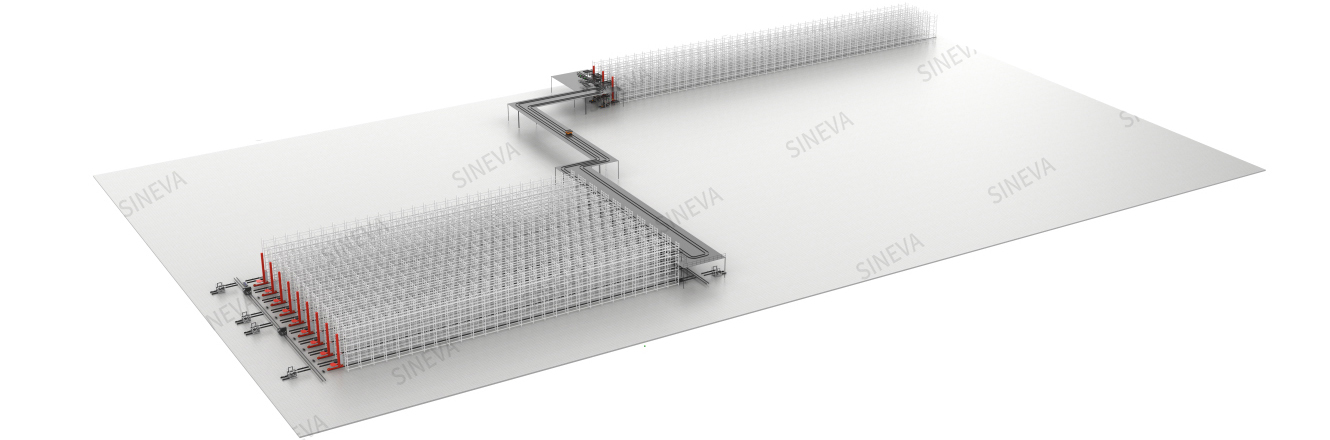

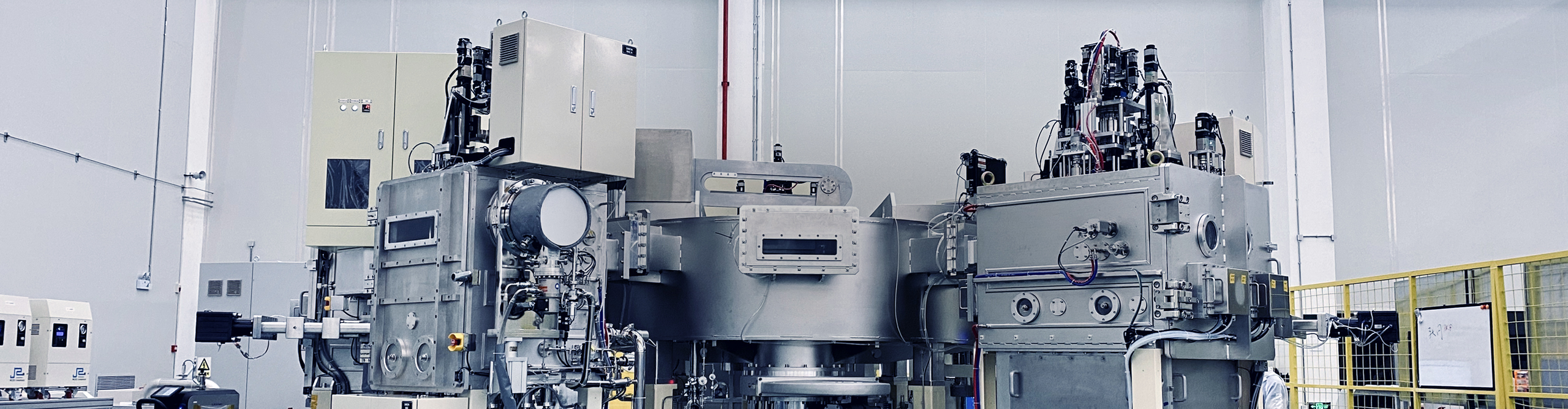

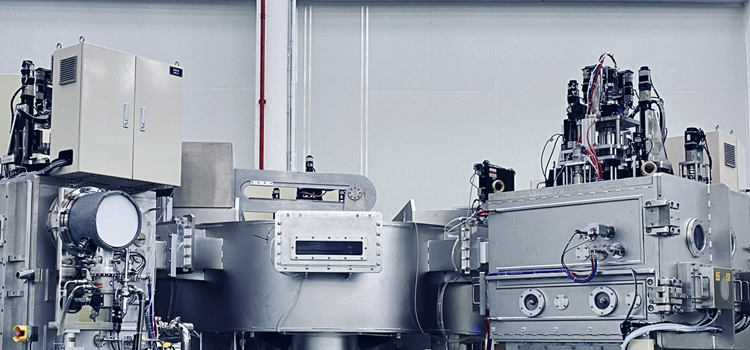

※ The three-dimensional warehouse of a domestic LCD panel leading enterprise The intelligent Warehouse System has 10700 storage spaces, 7 sets 16-meter stackers, 3 circular shuttles, WCS and WMS. The production handling area realizes the intelligent integration of the production line, unmanned automation and temperature & humidity control. Intelligent unmanned three-dimensional warehouse greatly improves staff work efficiency and reduces labor intensity. Combined with information management technology, we can effectively use the warehouse space to provide better services for customers in a fast, accurate and low-cost way. |

|

|

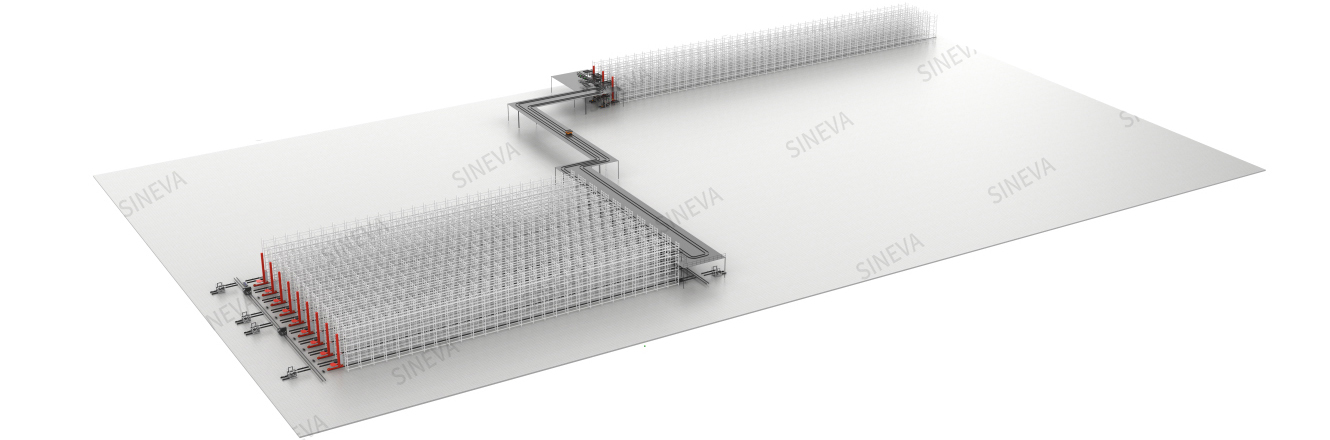

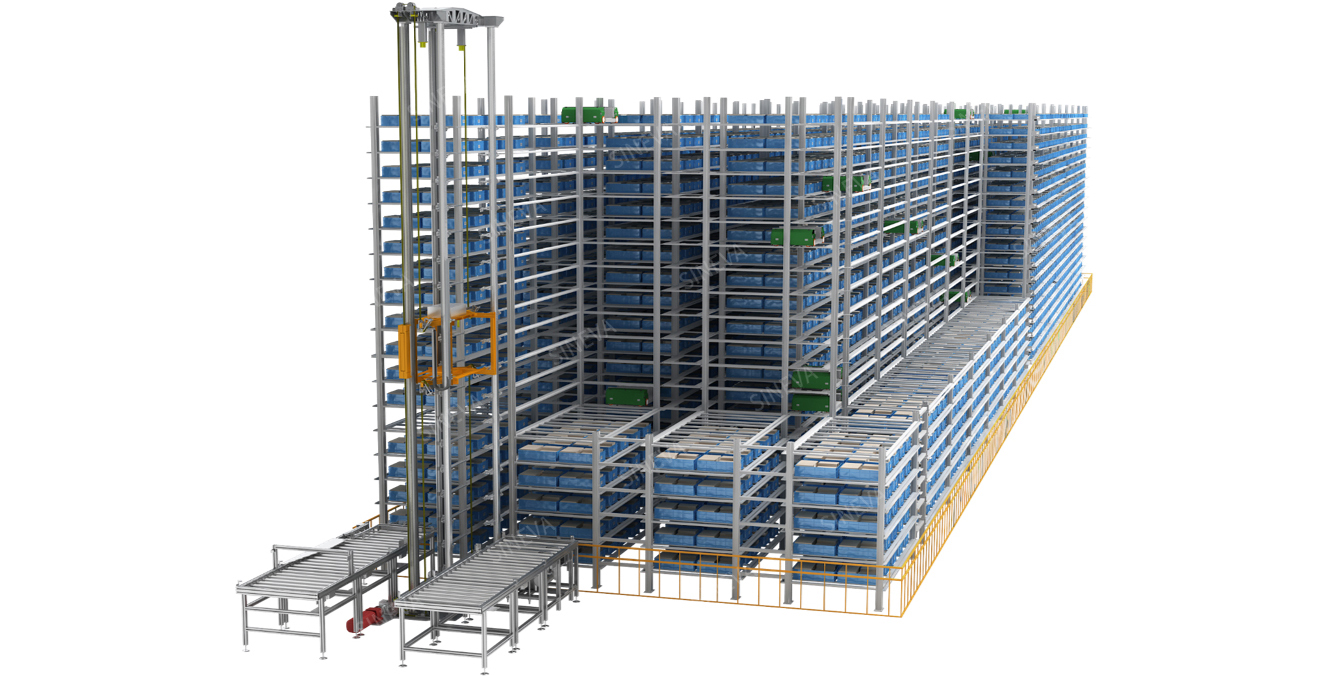

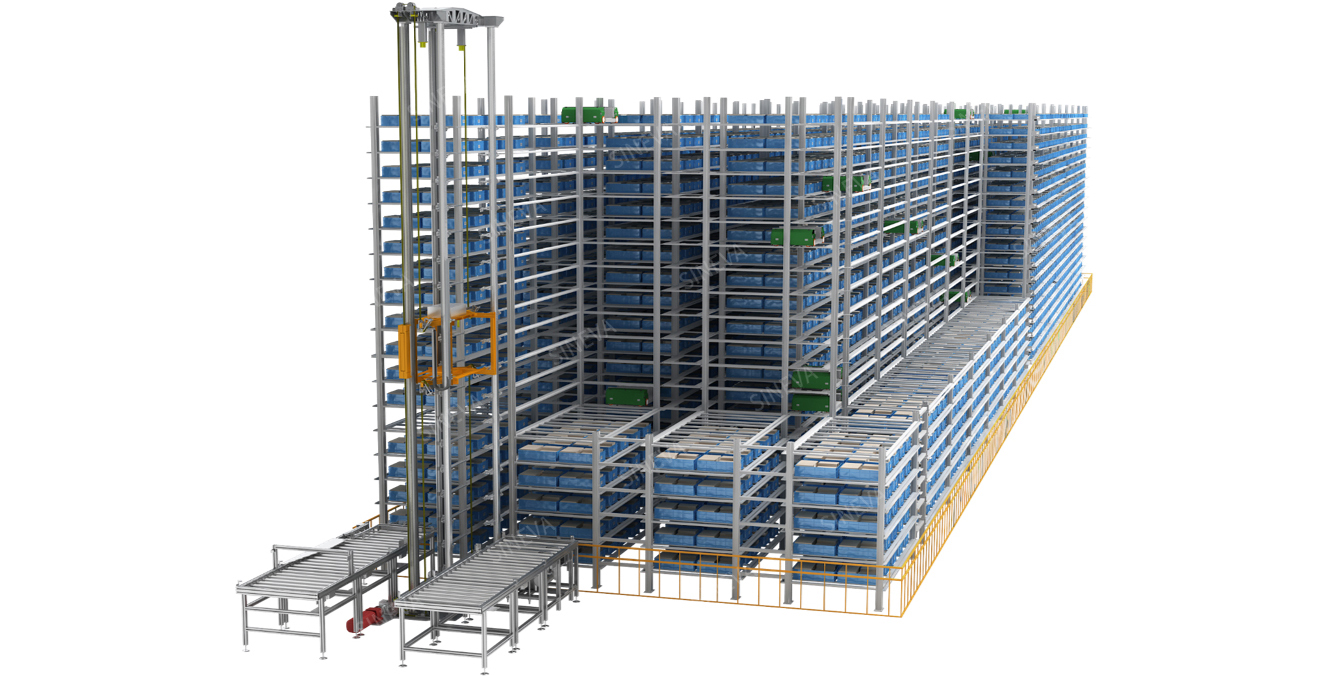

※ Case of new energy warehouse This intelligent shuttle garage in a photovoltaic industry has 12500 storage spaces, 1 hoist, 10 shuttle cars, WCS and WMS. The intelligent shuttle garage is composed of shuttle car, high-speed elevator, customized shelf, in and out transportation device and warehouse control system. Compared with the traditional warehouse, the intelligent shuttle garage has more efficient storage action, more competitive cost advantage, more environmental protection, energy saving and more flexible reservoir setting. |

Cases

|

|

※ The three-dimensional warehouse of a domestic 3C leading enterprise This intelligent warehouse solution has 4236 storage spaces, 5 double stretch stackers, 1 single stretch stacker, 1 double station linear shuttle, 1 WCS( Warehouse Control System) and 1 WMS( Warehouse Management System). The intelligent warehouse system is based on automatic storage equipment, high-rise shelves and advanced information management system, meet material storage needs, and improves the level of warehouse management. It improves warehouse operation efficiency through automated storage system, and the efficiency of storage materials in and out of the warehouse, reduce freight losses and investment in human resources, improve warehouse utilization which can bring economic benefits to enterprises. |

|

|

※ Three-dimensional warehouse of a domestic HVAC enterprise The intelligent Warehouse System has 8336 storage spaces, 12 heavy duty 1.5T stacker, double stretch stackers, 1 single stretch stacker, 4 one-track two-car systems, 1 SLV System, 1 WCS( Warehouse Control System) and 1WMS( Warehouse Management System). The automated three-dimensional warehouse realizes warehouse automation and transparent management information, and plans an automatic warehouse out and loading system, the seamless connection of material flow and information flow can be realized through the intelligent transfer line and the upstream production and processing workshop. |

|

|

※ The three-dimensional warehouse of a domestic LCD panel leading enterprise The intelligent Warehouse System has 10700 storage spaces, 7 sets 16-meter stackers, 3 circular shuttles, WCS and WMS. The production handling area realizes the intelligent integration of the production line, unmanned automation and temperature & humidity control. Intelligent unmanned three-dimensional warehouse greatly improves staff work efficiency and reduces labor intensity. Combined with information management technology, we can effectively use the warehouse space to provide better services for customers in a fast, accurate and low-cost way. |

|

|

※ Case of new energy warehouse This intelligent shuttle garage in a photovoltaic industry has 12500 storage spaces, 1 hoist, 10 shuttle cars, WCS and WMS. The intelligent shuttle garage is composed of shuttle car, high-speed elevator, customized shelf, in and out transportation device and warehouse control system. Compared with the traditional warehouse, the intelligent shuttle garage has more efficient storage action, more competitive cost advantage, more environmental protection, energy saving and more flexible reservoir setting. |

Back to list

Back to list Document dowload

Document dowload