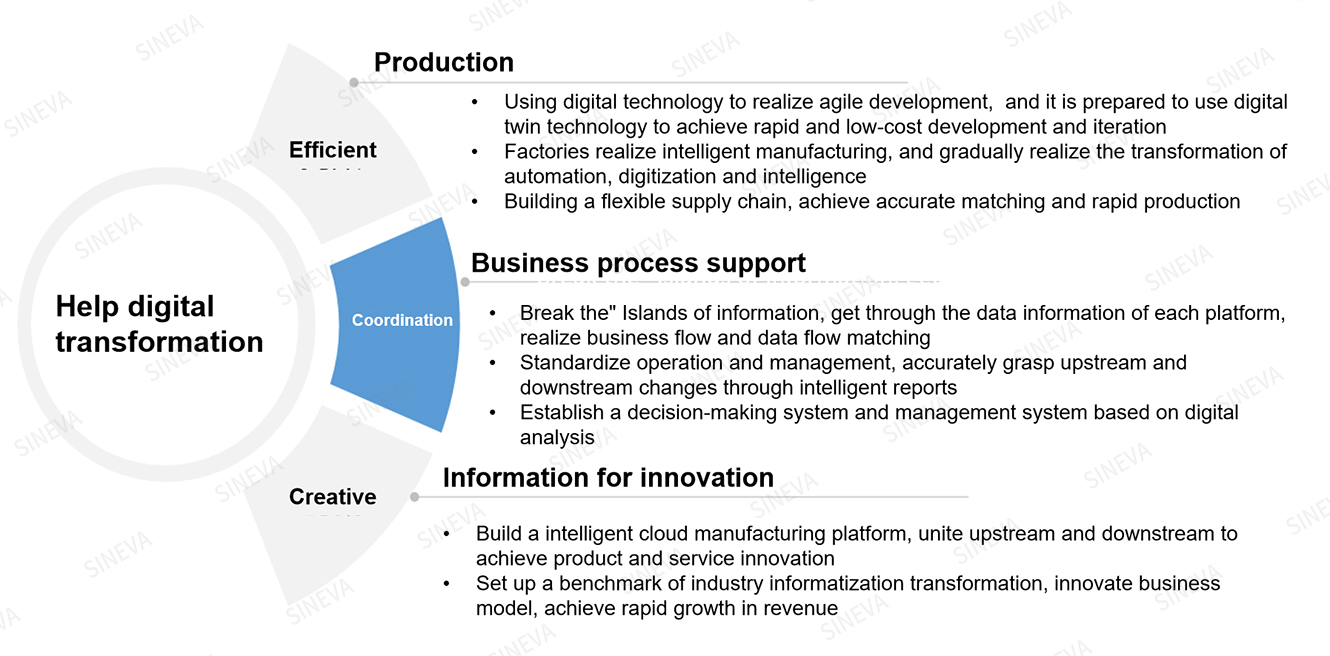

Product features

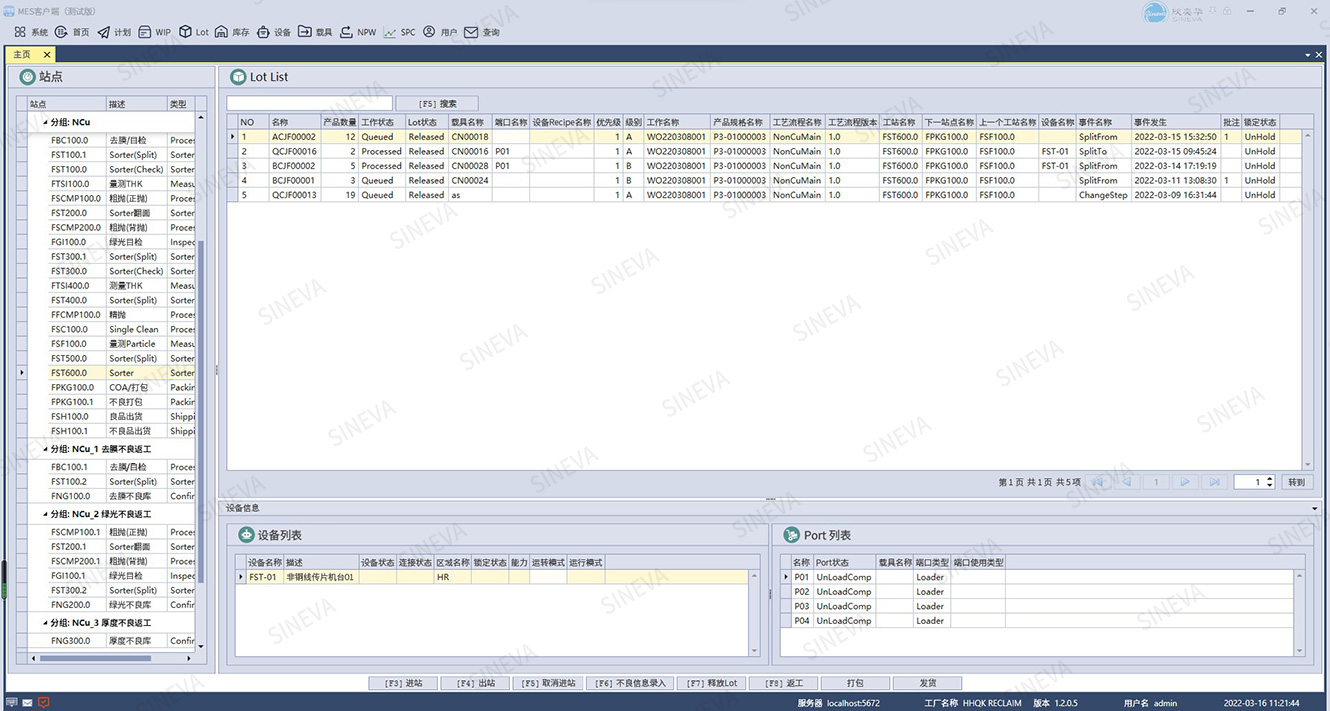

– Stable operation, flexible, expansibility

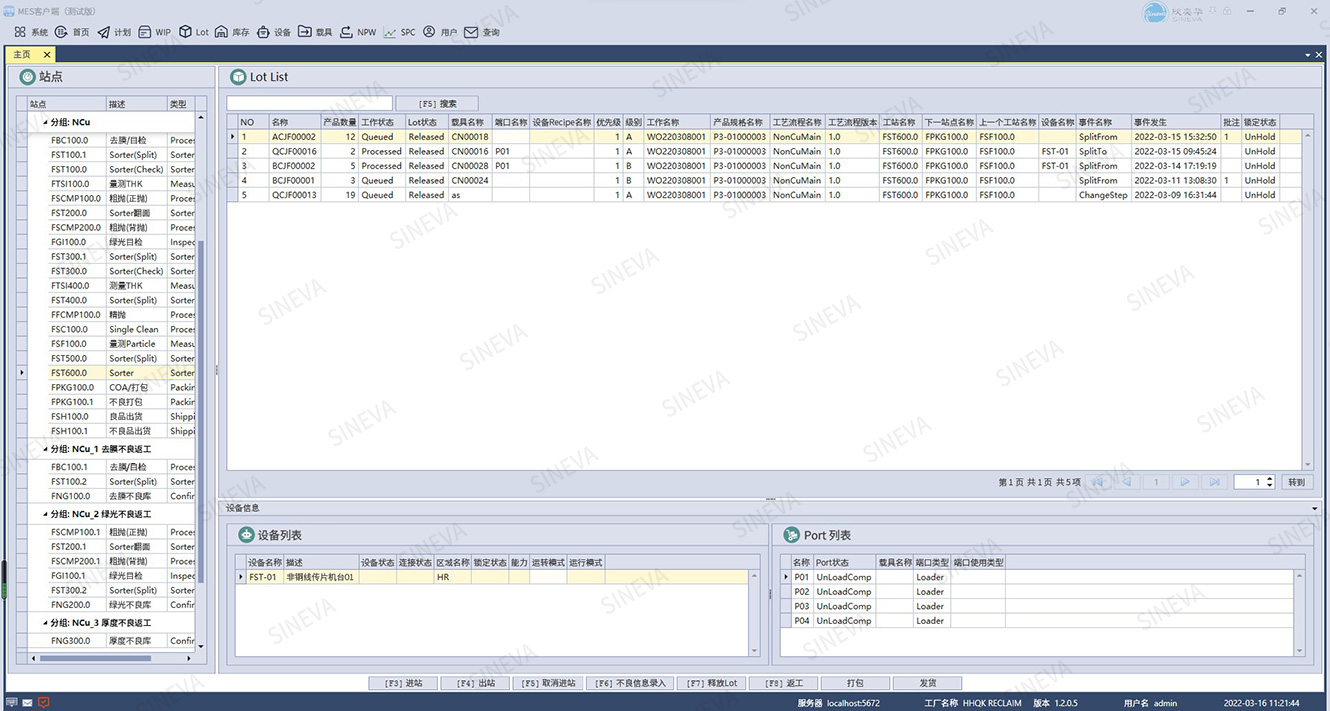

– Graphical system modeling and configuration tools

– Fast and friendly user interface

– Standardized automatic control system

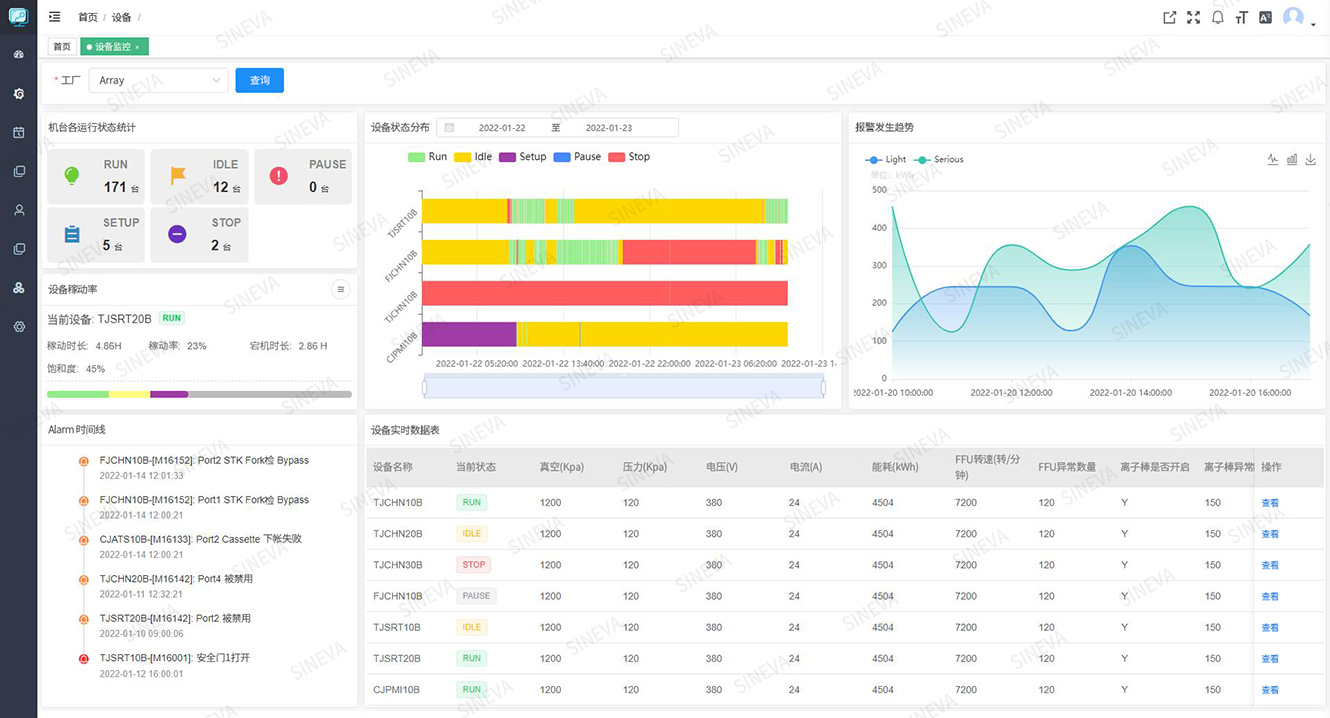

– Real time monitoring during production

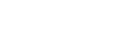

Core Technology

– Message middleware cluster deployment to achieve dynamic load balancing

– ORM object relational mapping to realize online database update

– .NET Core cross-platform technical support

Advantage effect

|

|

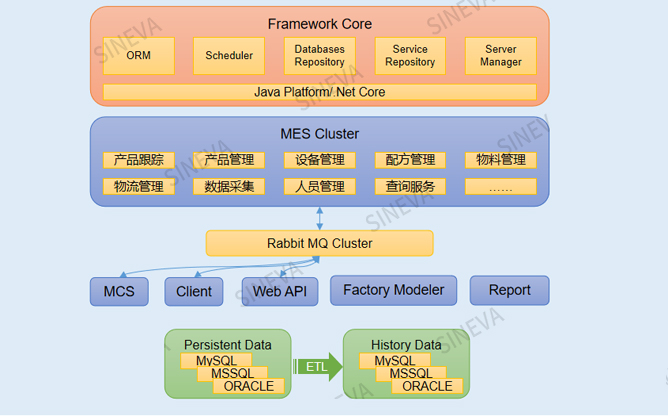

Fast and friendly user interface |

|

|

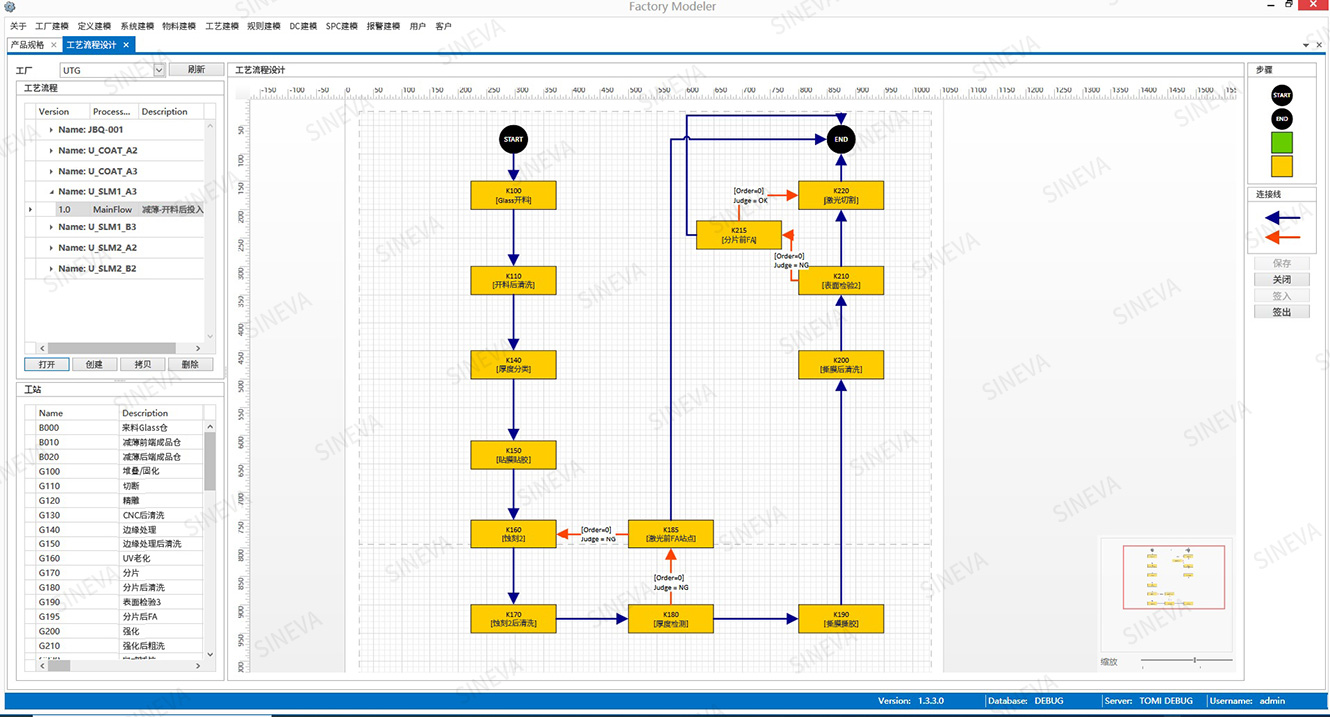

Flexible and drag drawing tool design process flow |

|

|

Multi-dimensional analysis of product quality |

|

|

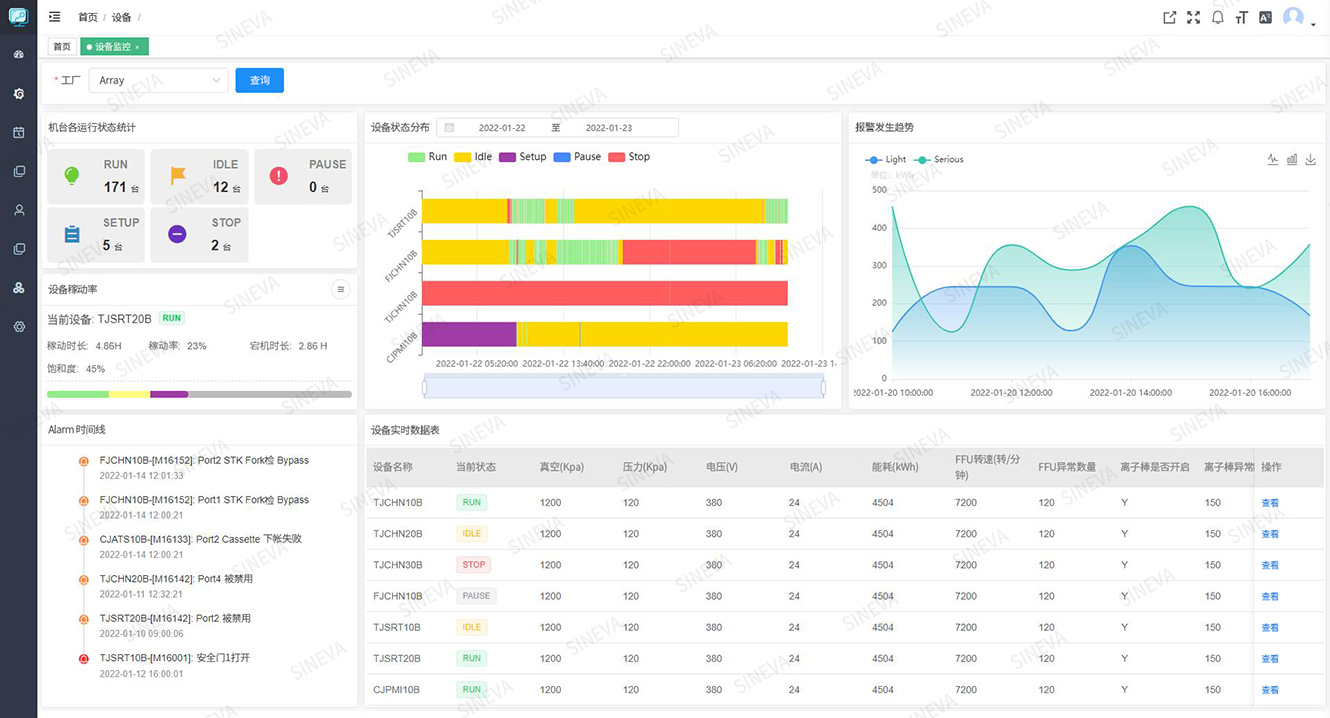

Monitor the production status of the whole plant |

Cases

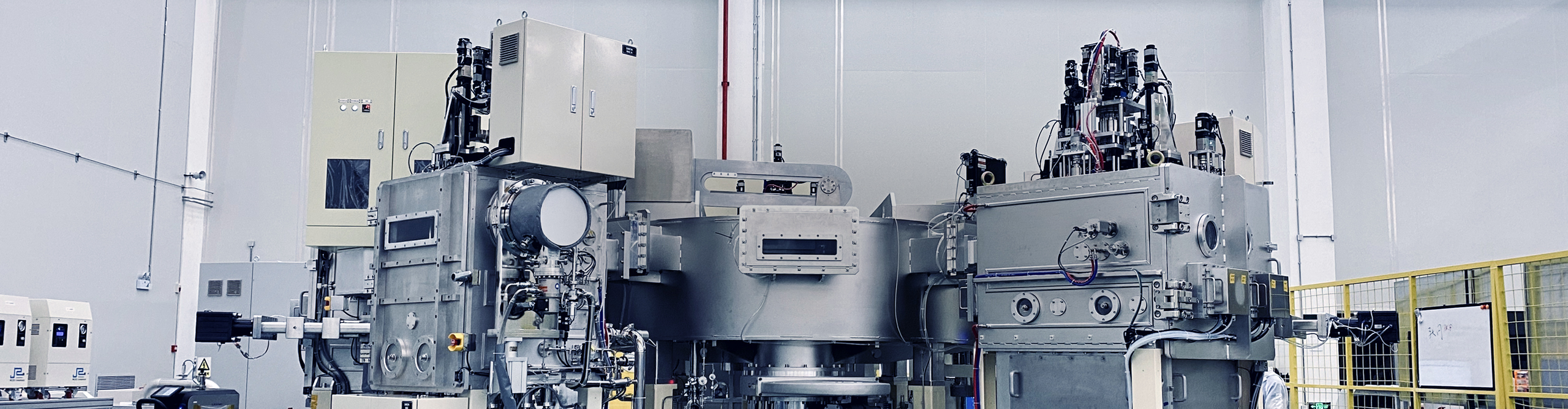

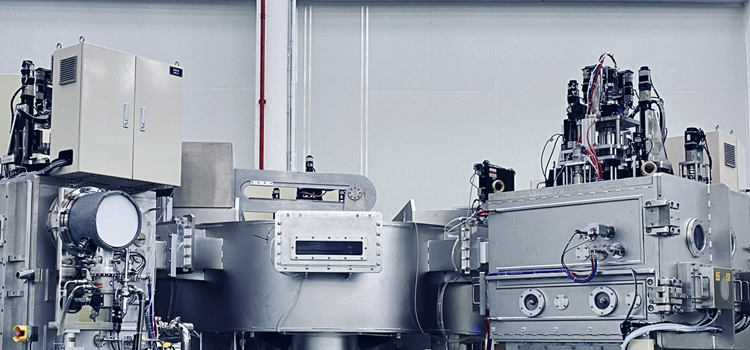

※ Ultra-thin Glass (UTG) Factory Digital Solution (UTG digital factory case in China)

|

|

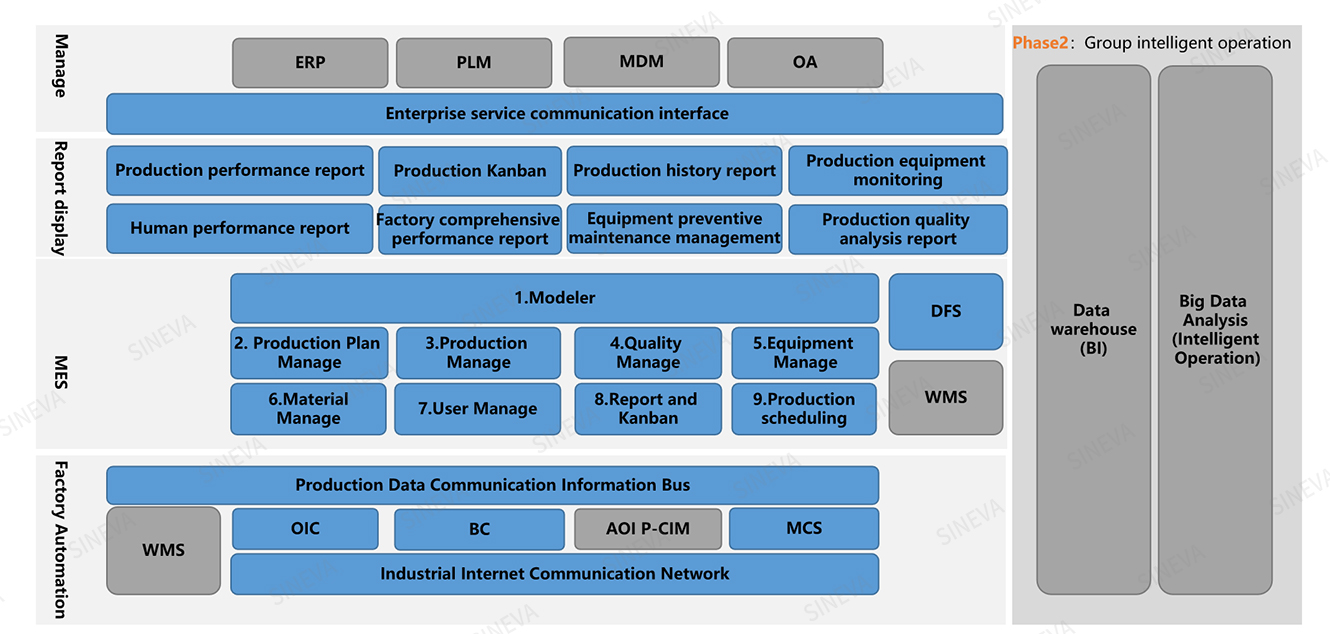

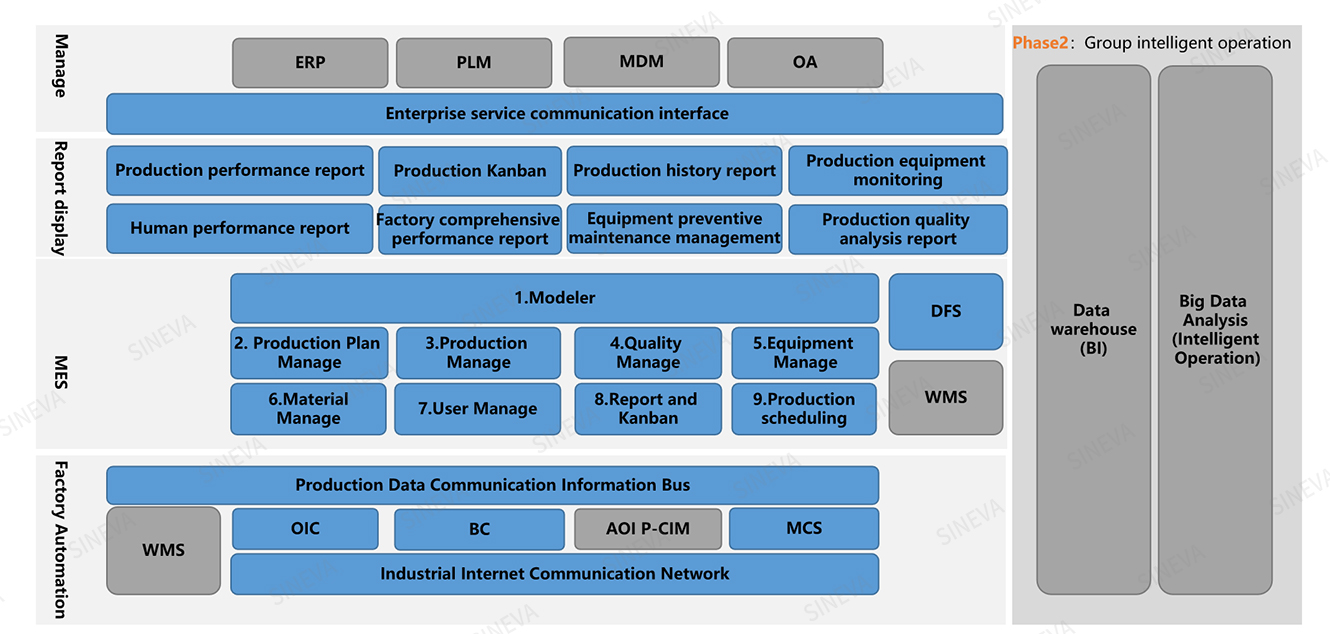

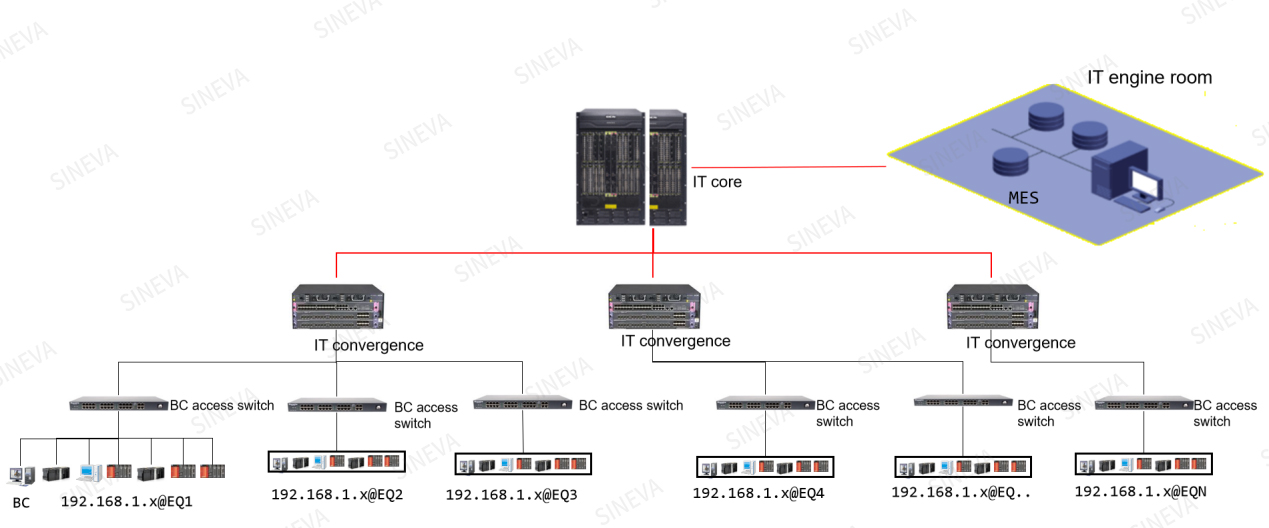

The overall work scope of the project includes BC, MCS, DFS and MES |

|

|

• Intelligent production scheduling

(1) The sales order is automatically disassembled into an executable work order, and then automatically released according to different process segments; (2)Automatically control the work order according to the process section, and report the completion status to ERP to achieve high-degree coordination of production status. |

|

|

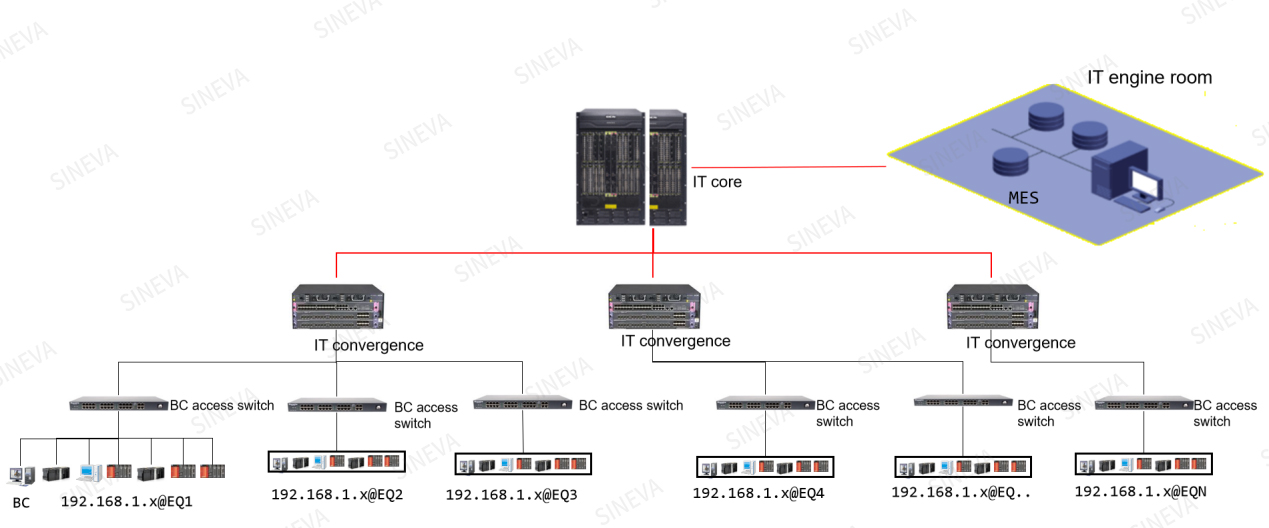

• Virtualization deployment scheme

(1)All BC data acquisition services are deployed on cloud servers which can greatly reduce hardware costs; (2)The cloud server adopts hyper-converged hardware solutions to enhance system security and maintainability. |

|

|

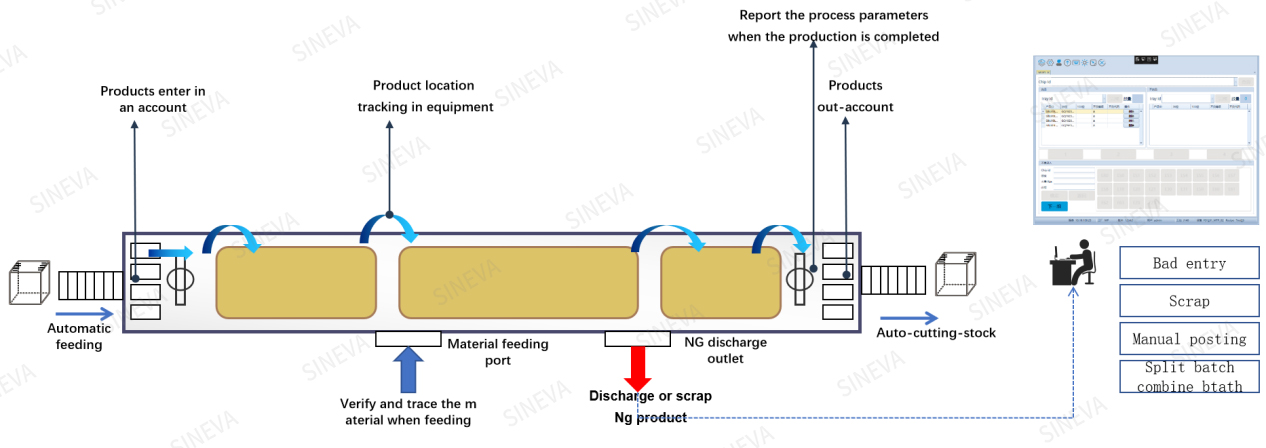

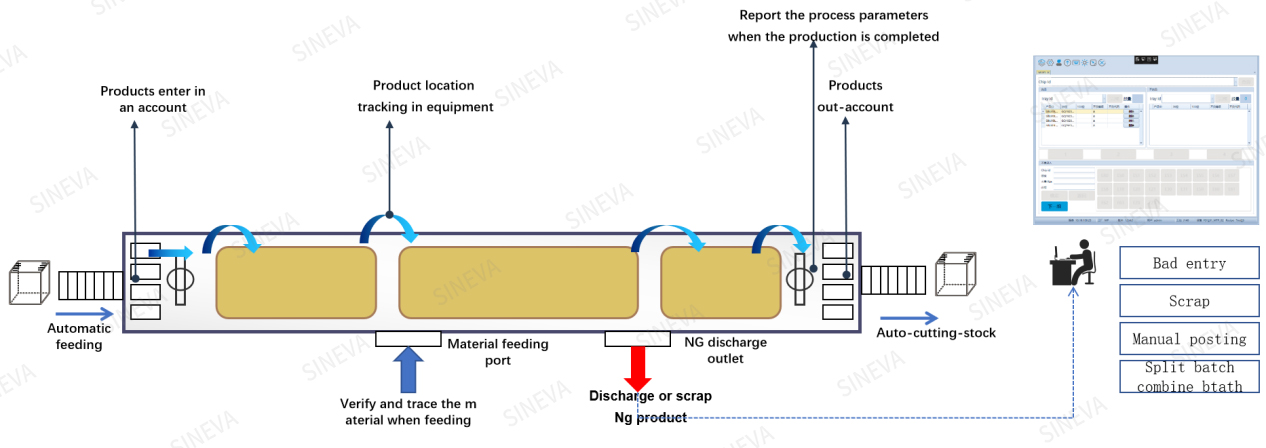

• Manufacturing tracking

The whole process of manufacturing can be clearly tracked,including :product import and export process tracing, product manufacturing process parameters tracing, materials batch verification and usage record tracking and NG or scrap tracing. |

|

|

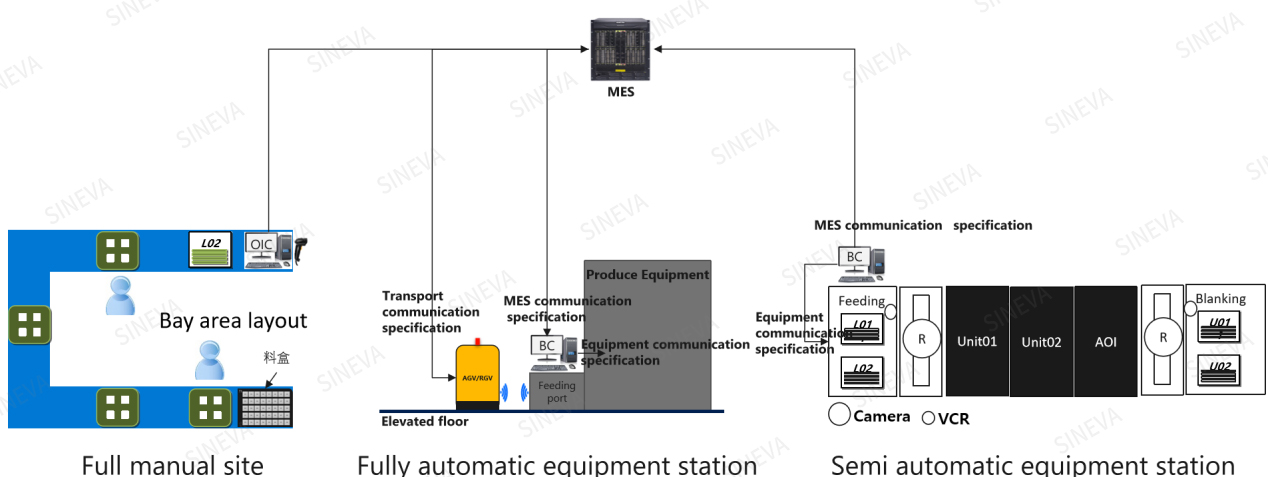

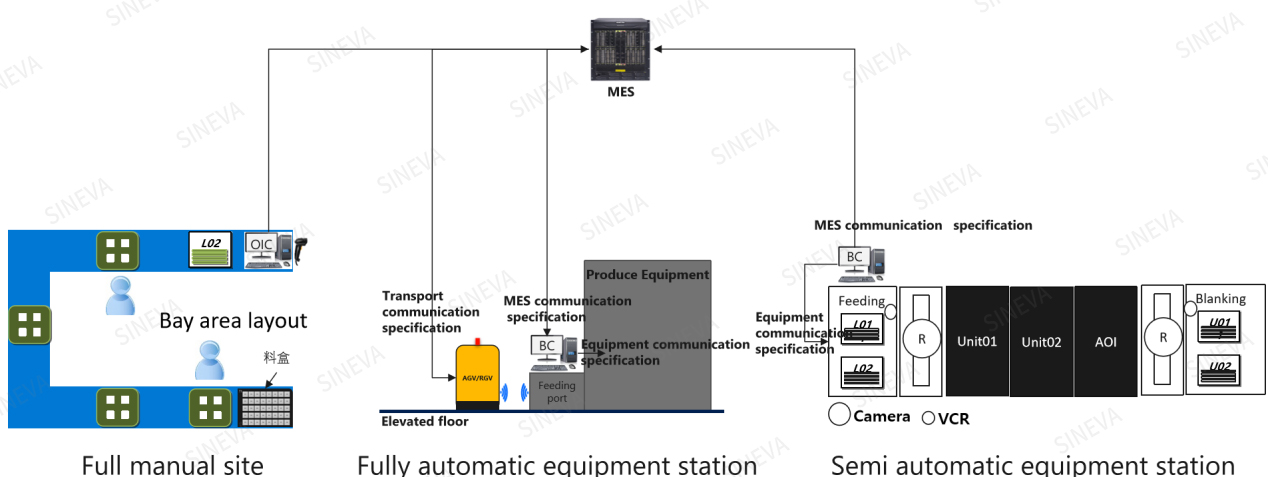

• Satisfy the communication control of all manual equipment, manual equipment, semi-automatic equipment and automatic equipment, and mature industry three level standardized communication specifications:

(1)MES communication Specifications:The message format definition is compatible with the pan-semiconductor industry standard and supports RabbitMQ, Tib RV, MQ and other common messaging middleware; (2)Equipment communication specifications:The message format definition adopts mature standards supported by many manufacturers in the industry,it supports Ethernet /WebAPI/ serial port /EIP/CC Link IE/ProfiNet/Modbus and other mainstream PLC/BC industrial communication control protocols; (3)Transport communication specifications:Message format definition is compatible with semiconductor SECSII standard (basically supported by transport equipment manufacturers), supports HSMS / webapi / bobcat and other mainstream communication protocols and method. |

Advantage effect

|

|

Fast and friendly user interface |

|

|

Flexible and drag drawing tool design process flow |

|

|

Multi-dimensional analysis of product quality |

|

|

Monitor the production status of the whole plant |

Cases

※ Ultra-thin Glass (UTG) Factory Digital Solution (UTG digital factory case in China)

|

|

The overall work scope of the project includes BC, MCS, DFS and MES |

|

|

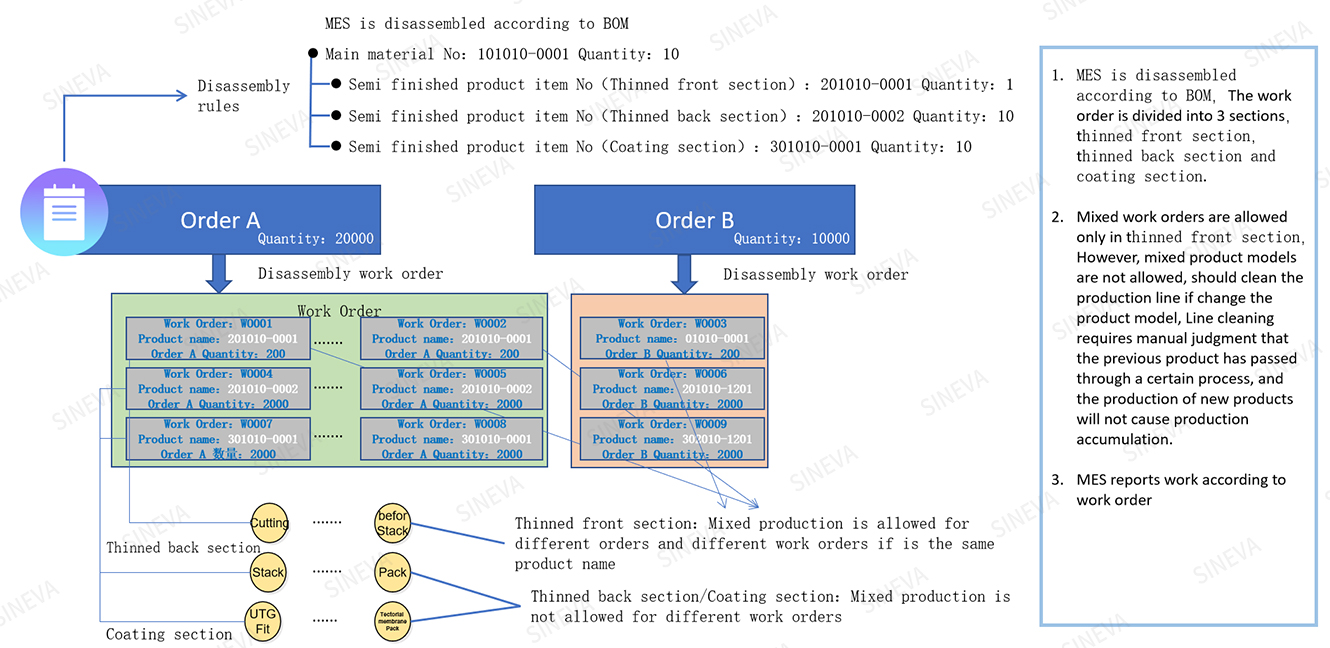

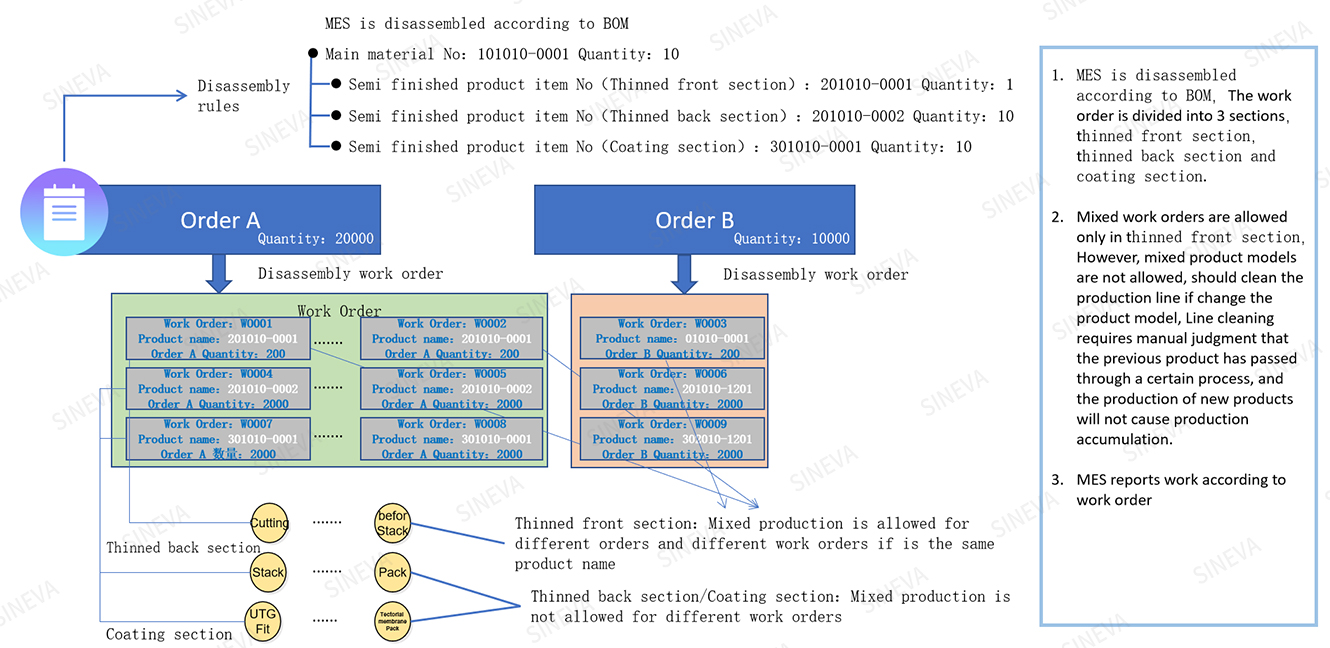

• Intelligent production scheduling

(1) The sales order is automatically disassembled into an executable work order, and then automatically released according to different process segments; (2)Automatically control the work order according to the process section, and report the completion status to ERP to achieve high-degree coordination of production status. |

|

|

• Virtualization deployment scheme

(1)All BC data acquisition services are deployed on cloud servers which can greatly reduce hardware costs; (2)The cloud server adopts hyper-converged hardware solutions to enhance system security and maintainability. |

|

|

• Manufacturing tracking

The whole process of manufacturing can be clearly tracked,including :product import and export process tracing, product manufacturing process parameters tracing, materials batch verification and usage record tracking and NG or scrap tracing. |

|

|

• Satisfy the communication control of all manual equipment, manual equipment, semi-automatic equipment and automatic equipment, and mature industry three level standardized communication specifications:

(1)MES communication Specifications:The message format definition is compatible with the pan-semiconductor industry standard and supports RabbitMQ, Tib RV, MQ and other common messaging middleware; (2)Equipment communication specifications:The message format definition adopts mature standards supported by many manufacturers in the industry,it supports Ethernet /WebAPI/ serial port /EIP/CC Link IE/ProfiNet/Modbus and other mainstream PLC/BC industrial communication control protocols; (3)Transport communication specifications:Message format definition is compatible with semiconductor SECSII standard (basically supported by transport equipment manufacturers), supports HSMS / webapi / bobcat and other mainstream communication protocols and method. |

Back to list

Back to list